Preview

- Grade(s): 9-12

- Time: 1.5 weeks

Description

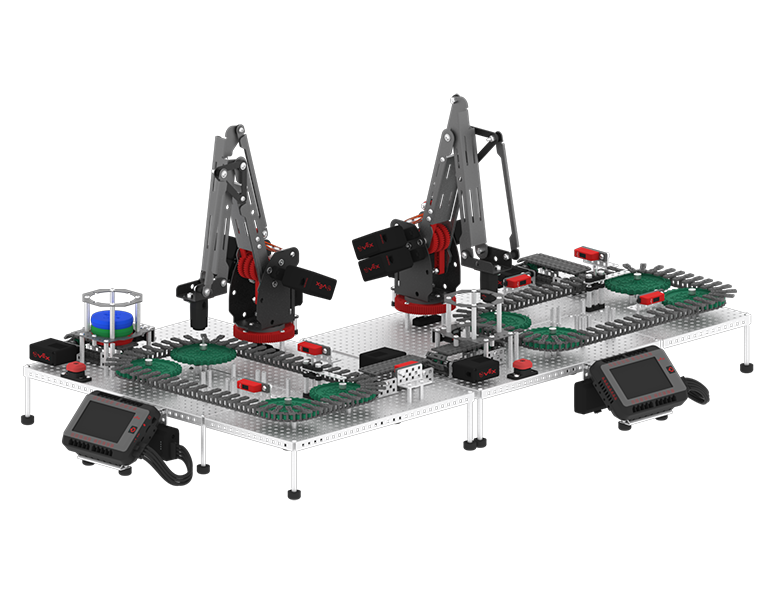

- Students will work together to explore Cooperative Systems and Boolean variables in order to sort disks. Students will first learn about robot to robot communication, before creating a project to sort two green disks.

- Students will add a Disk Feeder to the Workcell to introduce multiple disks to the Workcell in an autonomous fashion.

- The first green disk will be picked up and dropped off to a known location using the arm mounted on the VEX V5 Workcell, while the second green disk is diverted off of the Exit Conveyor.

- Students will be introduced to using Boolean variables in their VEXcode V5 project to track if a green disk has already been picked up and placed. This allows any other green disks introduced via the Disk Feeder to be diverted off to the Exit Conveyor.

- For the final activity of the Lab, students will be challenged to sort colored disks. They will use either one or two systems to pick up and drop off one disk of each color to a known location, and then divert off any additional disks.

Essential Question(s)

- How do robotic systems effectively work together to move products through the manufacturing process?

Understanding(s)

Students will understand:

- What is the process of handshaking with robot to robot communication, and why it is important.

- How to attach and utilize the Disk Feeder in the Workcell.

- The building of a project to utilize Boolean variables in order to effectively track which colored disk has already been picked up and placed.

Objective(s)

- Attach the Disk Feeder to the Entry Conveyor.

- Adjust the parameters of the Entry Conveyor in order to properly use the Disk Feeder.

- Create a Boolean variable to track the placement of green disks.

- Outline the goals of the project using comments.

- Explain the flow of the [If then else] block in the project.

- Create a project to sort two green disks using sensors.

Vocabulary

- Handshaking

- the establishment of communication between two or more robotic systems.

- Robot to robot communication

- the process of robots passing information/signals back and forth between one another.

- Sensor communication

- using sensors to communicate between robotic systems. An item may be passed from one system to the next and the item triggers a sensor, communicating its presence.

- Wired communication

- with this type of communication the robots are hardwired together using some type of communication cabling.

- Wi-Fi communication

- uses Wi-Fi protocols to communicate packets of information between the two robotic systems.

- Bluetooth communication

- uses Bluetooth radio waves to connect the two robotic systems together.

Materials Needed

| Quantity | Materials Needed |

|---|---|

| 1 |

VEX V5 Workcell |

| 1 |

VEXcode V5 |

| 1 |

Engineering Notebook |

| 1 |

Device to run VEXcode V5 |

| 1 |

Micro-USB cable |

| 2 |

Colored Disks (2x green) |

Educational Standard(s)

- Next Generation Science Standards HS-ETS1-3: Evaluate a solution to a complex real-world problem-based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts.

- Computer Science Teacher Association 3A-AP-18: Create artifacts by using procedures within a program, combinations of data and procedures, or independent but interrelated programs.

- Computer Science Teacher Association CSTA 3A-AP-13: Create prototypes that use algorithms to solve computational problems by leveraging prior student knowledge and personal interests.

- Computer Science Teacher Association 3A-AP-17: Decompose problems into smaller components through systematic analysis, using constructs such as procedures, modules, and/or objects.

Go to this page in the Knowledge Base to see a cumulative list of VEX V5 Workcell STEM Labs standards.