Preview

- Grade(s): 9-12

- Time: 0.5 week

Description

Students will use the VEX V5 Workcell to explore the Cartesian coordinate system. Students will download a project, then manually move the arm mounted on the V5 Workcell. They will observe how movement changes the (x, y, z) coordinates displayed on the V5 Brain’s screen. Then, students will find the coordinates of four different points on their Workcell. Students will also explore different robot configurations, and their limits of motion.

Essential Question(s)

What are robotic configurations and how do they define a robot’s motion?

Understanding(s)

Students will understand:

- What actuators are: how are they driven, and what factors would determine the best actuator to be chosen for a robot?

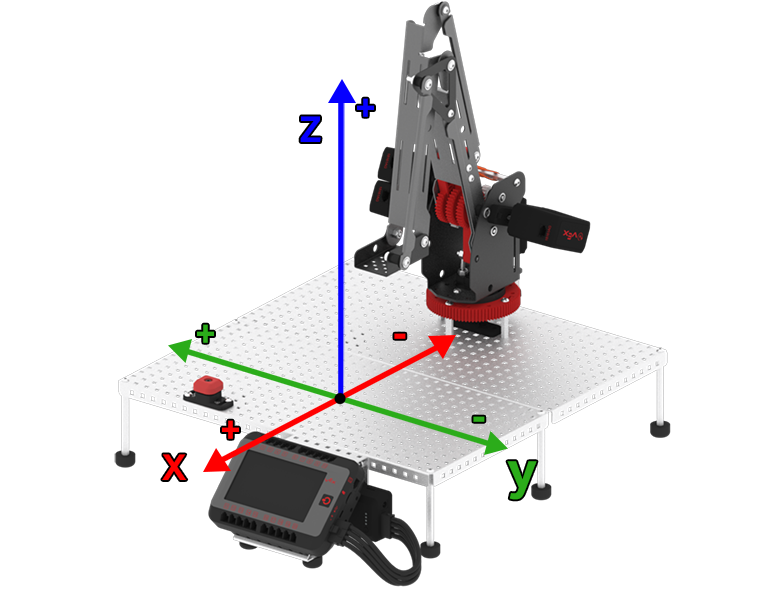

- How to use the Cartesian coordinate system with the “Arm Display Position” example project to identify the location of the arm mounted on the V5 Workcell in real time.

Objective(s)

- Explain why calibration is important in regards to the operation, accuracy, and repeatability of industrial robots.

- Identify the six types of industrial robotic configurations and match the V5 Workcell to the configuration it represents.

- Recognize what factors define the movements of robots.

- Identify different actuators such as hydraulics, pneumatics, and electrical motors.

- Follow a discrete procedure to manually jog the robotic arm.

- Identify and label the different axes addressed during manual jogging and recognize the (x,y,z) coordinates from the V5 Brain after the arm has been moved manually.

Vocabulary

- Calibration

- A standard starting point or zero point when measuring. This is called a calibration point. It is important for robots to be calibrated so they can use a standard point to measure their movements. Moving to a calibration point is called calibration.

- Axes of Motion (Degrees of Freedom)

- Possible movements of an object are: forward/backward, side to side, upward/downward, or rotate. Each of these motions is known as an axis of motion, or sometimes referred to as a degree of freedom of movement. These movements can be combined to move anywhere within three-dimensional space.

- Major Axes

- The major axes of a robotic arm move the tool to the workpiece.

- Minor Axes

- The minor axes of a robotic arm, orient the tool to do the work.

- Work Volume (Envelopes)

- The workspace a robot moves within.

- Singularity

- A robot’s structure can limit the amount it can move within its workspace. An area in which a robot cannot move is called a singularity.

- Cartesian

- This robot configuration allows its tool to move along the axes of the Cartesian (x,y,z) coordinate system. This means the robot’s tool can move forward/backward (x-axis), side to side (y-axis), and upward/downward (z-axis). This creates a box-like work envelope.

- Cylindrical

- This is a robot configuration where its tool can rotate around a central axis. The tool can also move towards and away from the central axis, plus up and down the central axis. These motions create a workspace in the shape of a cylinder.

- Spherical

- A robot configuration that has its tool rotate around a central axis. The tool can also rotate around a second axis which is placed at a 90-degree angle on the central axis. In addition, the tool can move back and forth along an axis. The tool motion created by these motions sweeps out a workspace shaped like a sphere.

- Selective Compliance Articulated Robot Arm (SCARA)

- A type of robot configuration that uses pivot points to allow its tool to move in a combination of the Cartesian and the cylindrical motions. This allows the tool to move quicker and can move easier in certain motions, such as moving in an arc.

- Articulated

- This is the type of robot which is typically pictured as an industrial robot. As a minimum, it would have at least a shoulder joint, an elbow joint, and a wrist joint. However, many examples of these configurations can have several other axes. The arm mounted on the V5 Workcell is an example of an Articulated configuration.

- Delta (Parallel)

- This type of configuration can move the robot’s tool the fastest of all of the robot configuration types. It uses parallel linkages to allow its tool to quickly sweep out its workspace.

- Hydraulics

- This type of actuator uses a pump to pressurize hydraulic fluid. Values release the fluid through hydraulic hoses. The pressure in the hoses can cause the shaft of a hydraulic cylinder to move out or move in. The pressure in the hoses can also cause the shaft of a rotational hydraulic actuator to spin.

- Pneumatics

- This type of actuator uses an air compressor to pressurize air. Valves release the air pressure through pneumatic tubing. The air pressure in the tubing can cause the shaft of a pneumatic cylinder to move out or move in. The pressure in the pneumatic tubing can also cause the shaft of a pneumatic rotary actuator to spin.

- Electric Motors

- These actuators convert electrical energy into rotational mechanical energy which causes a shaft to spin. There are electric motors that are powered by Direct Current (DC) and electric motors which are powered by Alternating Current (AC).

- Stepper Motors

- This type of motor uses Direct Current (DC) and the rotation of its shaft is divided into a number of equal steps for better control of the movement of the shaft.

- Servo Motors

- This type of motor has sensors that can be used to control things like position, speed, and acceleration of the motor’s shaft.

Materials Needed

| Quantity | Materials Needed |

|---|---|

| 1 |

VEX V5 Workcell |

| 1 |

Build Instructions |

| 1 |

VEXcode V5 |

| 1 |

Engineering Notebook |

| 1 |

Device to run VEXcode V5 |

| 1 |

Micro-USB cable |

Educational Standard(s)

- Next Generation Science Standards (NGSS) HS-ETS1-2: Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering.

- International Society for Technology in Education ISTE 5c: Students break problems into component parts, extract key information, and develop descriptive models to understand complex systems or facilitate problem-solving.

- Common Core State Standards CCSS.ELA-LITERACY.W.11-12.2: Write informative/explanatory texts to examine and convey complex ideas, concepts, and information clearly and accurately through the effective selection, organization, and analysis of content.

Go to this page in the Knowledge Base to see a cumulative list of VEX V5 Workcell STEM Labs standards.