Getting Ready for Competition

| Quantity | Materials Needed |

|---|---|

| 1 per group |

V5 Workcell |

| 1 per group | |

| 1 per group |

Engineering Notebook |

| 1 per group |

Device to run VEXcode V5 |

| 1 per group |

Micro-USB cable |

In this section, you will be introduced to different tips and tricks as well as troubleshooting techniques to prepare you for competition.

You will first explore different techniques to troubleshoot, such as checking the mastering values, sensor values, and ensuring the correct blocks are being used in a project before diving into how to make the Workcell your own.

Check the mastering values

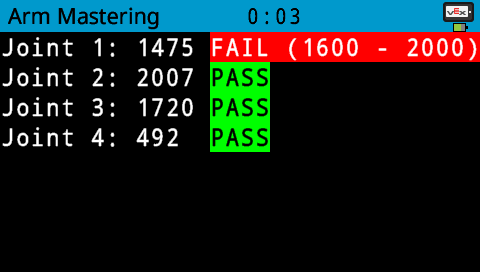

The mastering values could change or even fail if the Workcell has been bumped, transported, or edited to add or remove building materials. Moving the arm on the Workcell with quick and hard movements could also cause the mastering values to change.

View the 'Mastering Values' page from the Seek section to record new mastering values if any of the joints are failing, or the Workcell is not moving accurately.

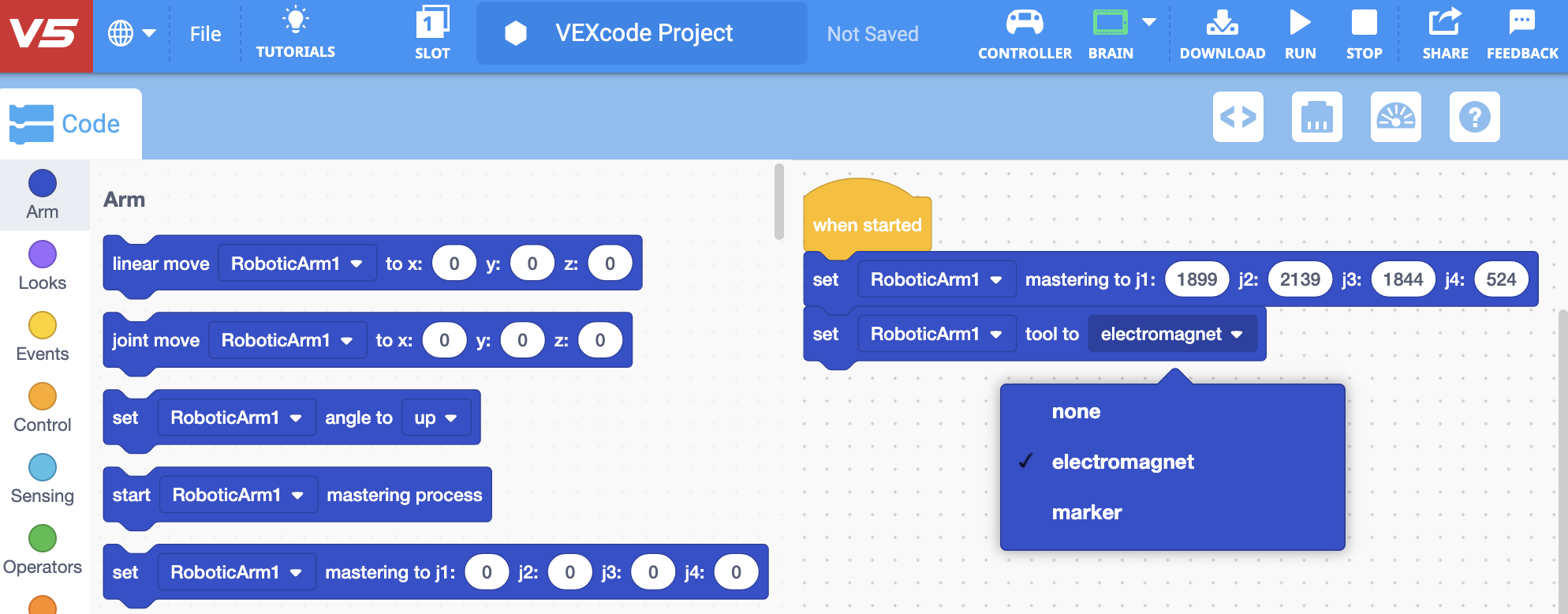

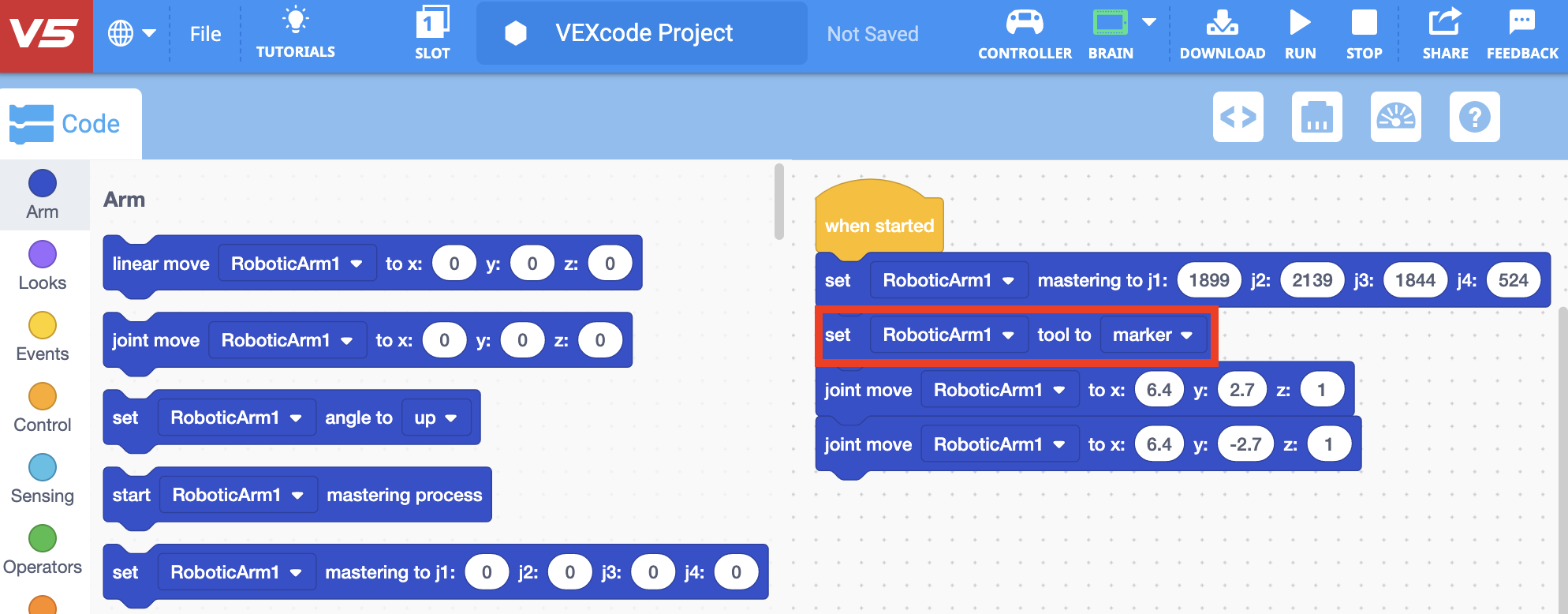

Ensure the [Set tool] block is set

When obtaining coordinate location values, if the [Set tool] block is not set correctly, the values may not be reported correctly. Ensure the [Set tool] block is set correctly in the project before obtaining any location values.

The [Set tool] block should be set correctly in a project before using any movement blocks, such as the [Linear move] block or the [Joint move] block.

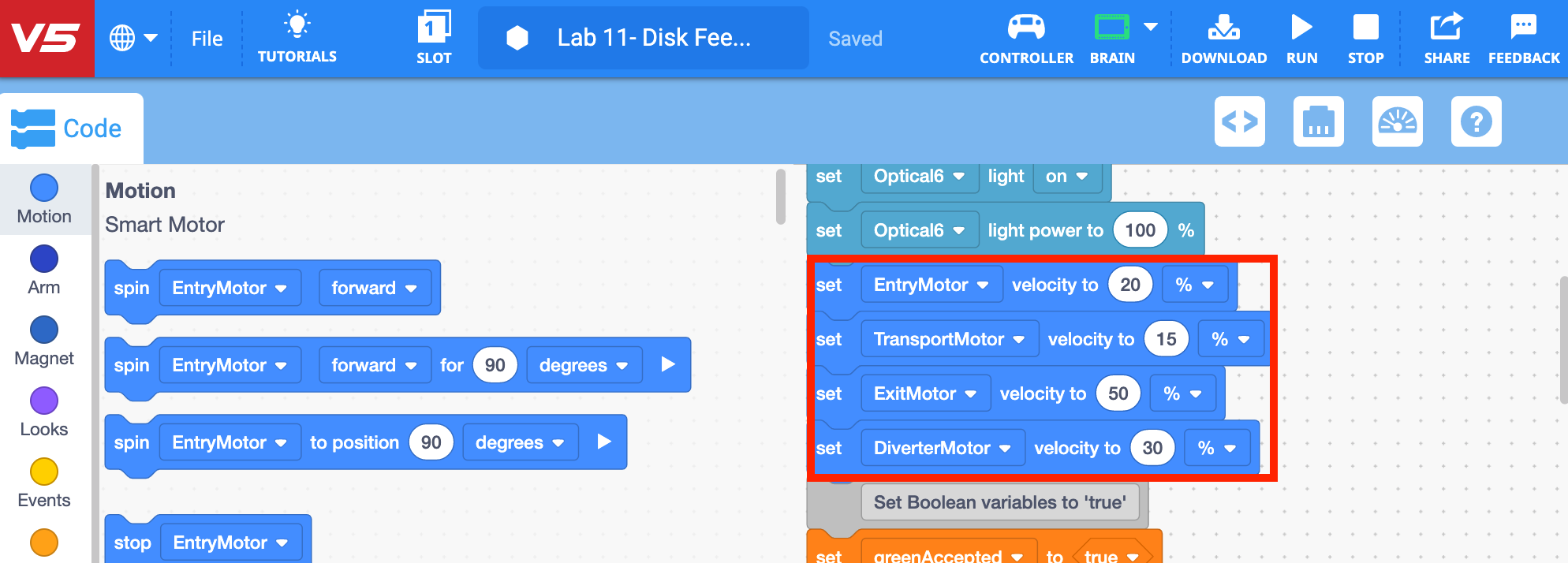

Ensure motor speeds are accurate

When spinning the individual motors of the conveyors on the Workcell, it is important to check to make sure the movements are not too quick that they cannot transport disks correctly.

The [Set motor velocity] blocks can be adjusted to increase and decrease the velocity of the motors.

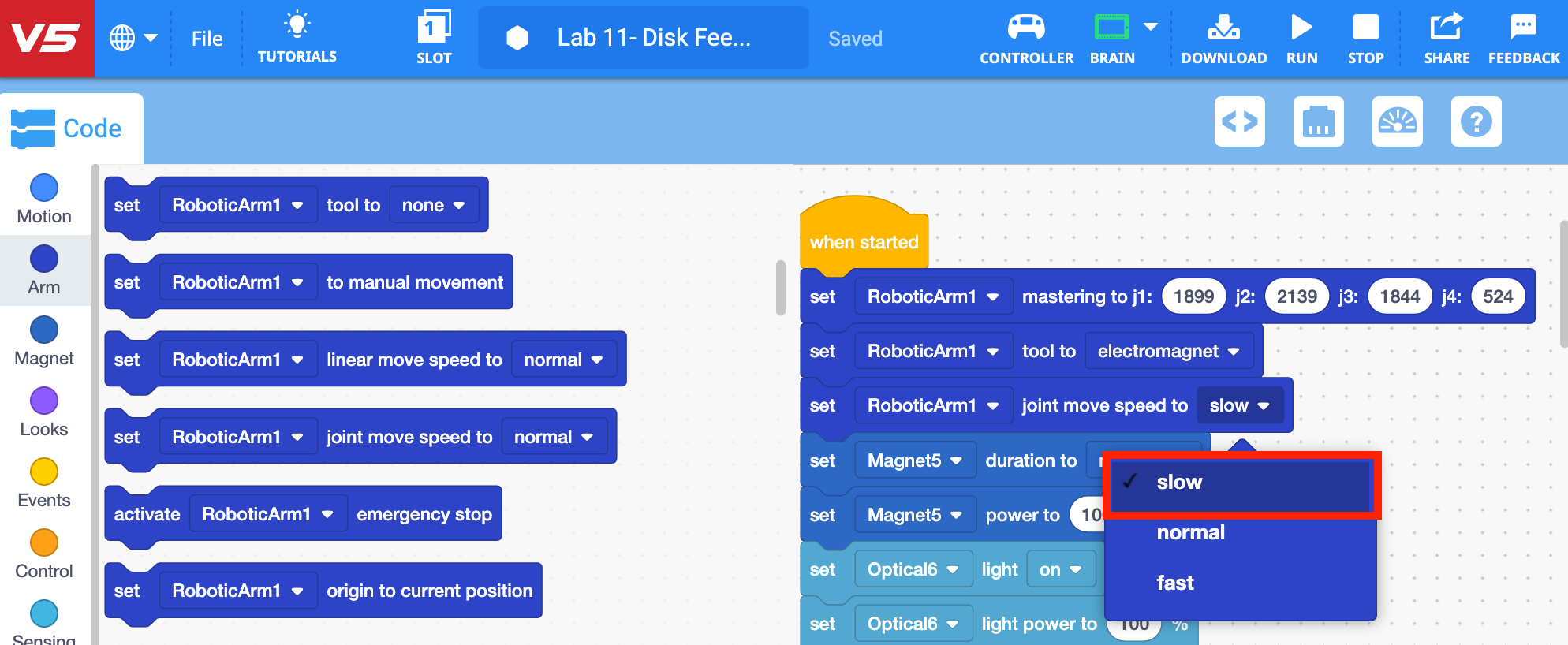

When coding the arm on the Workcell, reducing the linear and joint move speeds allows for more precise movements.

Use the [Set linear move speed] and [Set joint move speed] blocks to better control the arm's movements.