Improving the Workcell Hardware

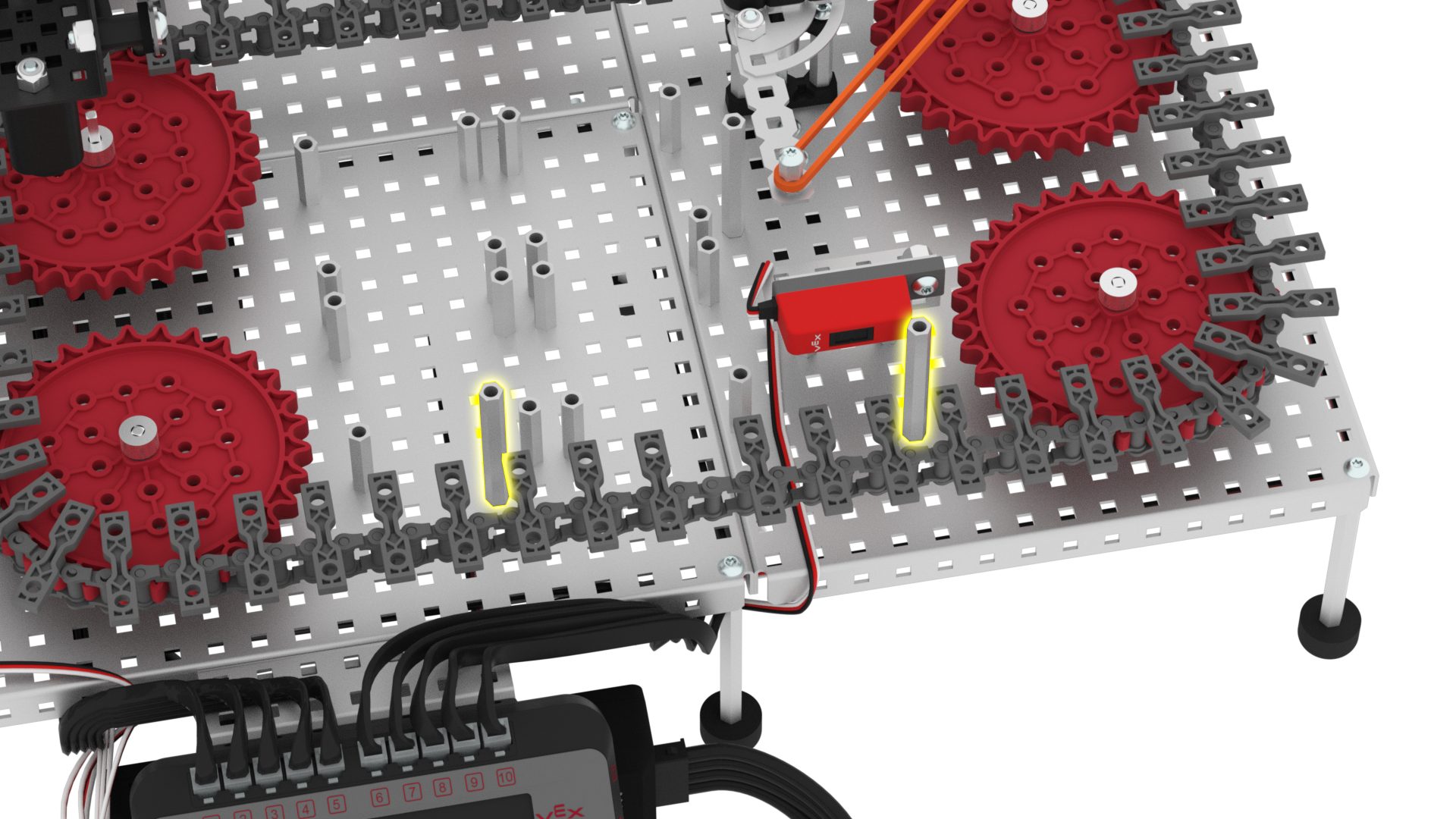

Improve the flow of disks

When the Disk Feeder is being used the disks may fall off of the conveyor belts.

An option is to add standoffs around the conveyors.

This can help guide the disks along the conveyors to ensure that no disks fall off.

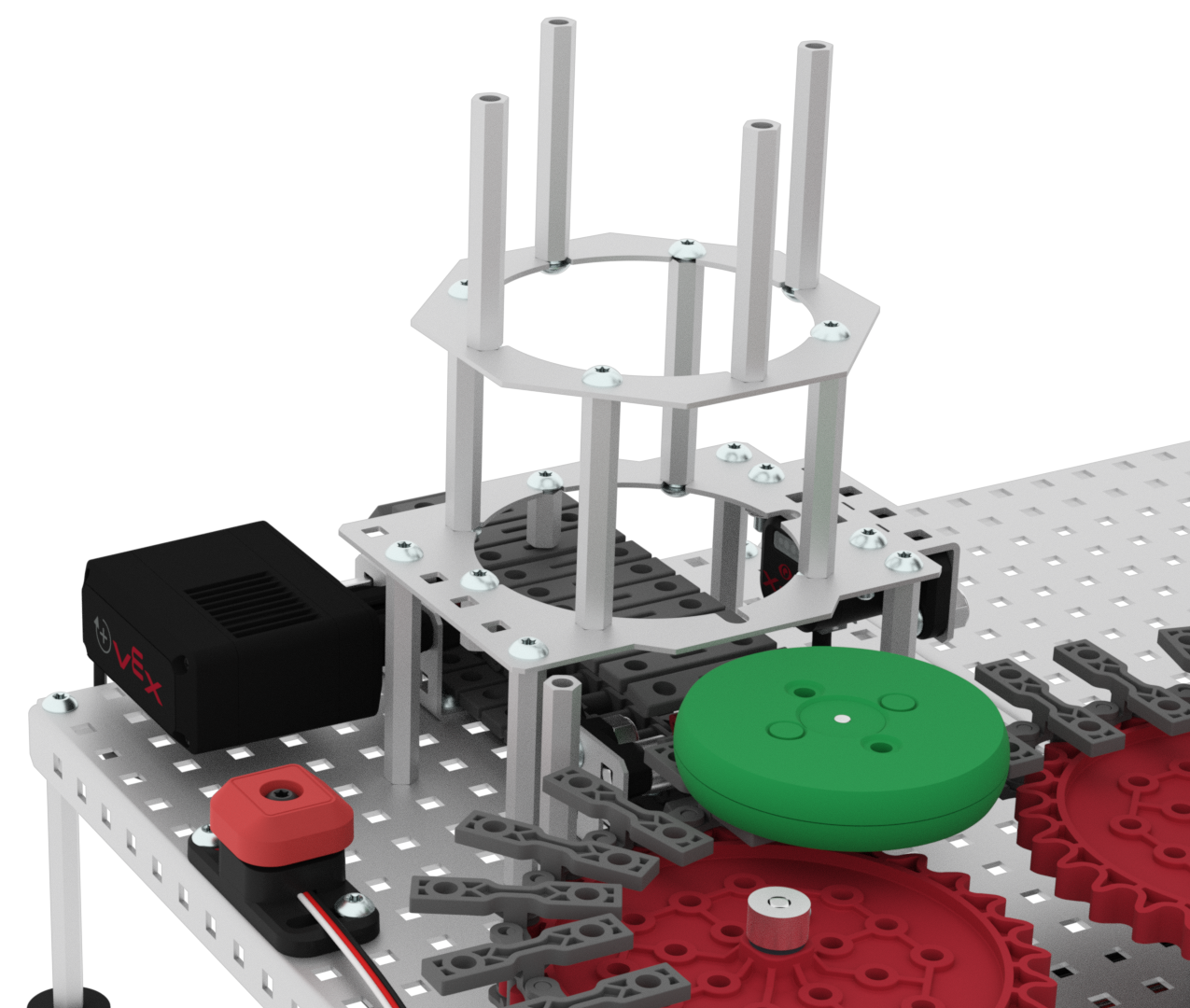

As you sort more disks, you may need to store more of them in the Disk Feeder.

Another option is to increase the height of the Disk Feeder in order to hold more disks by using standoffs.

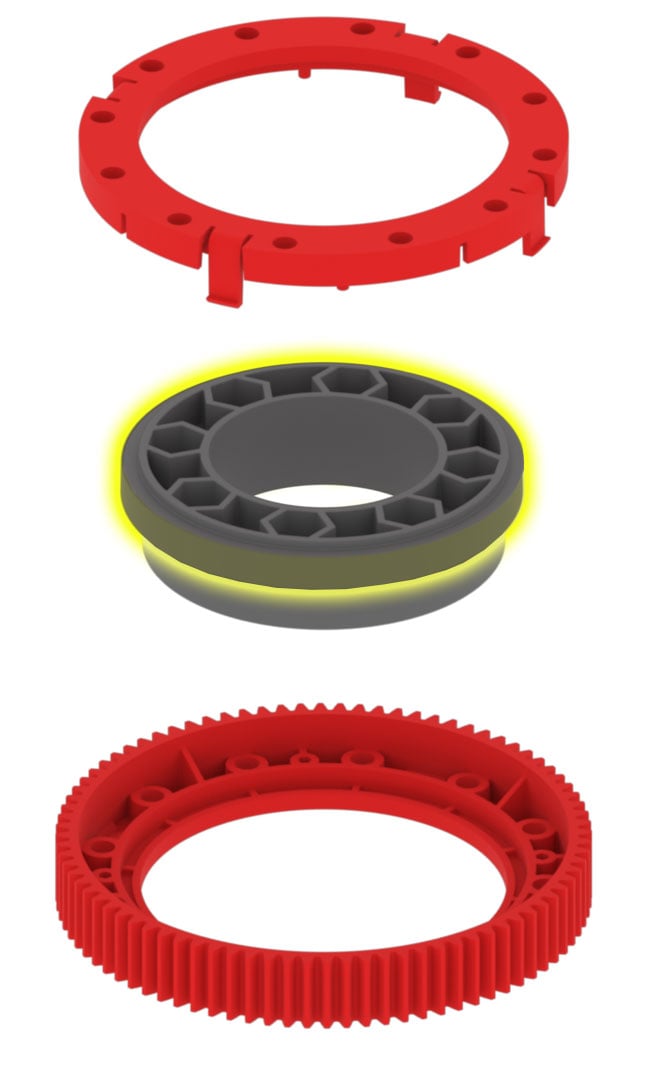

Lubricating the turntable

As your arm moves around the Workcell, you may notice that side-to-side movements are not as smooth. If this is the case, the turntable of the arm may need lubricated.

Lubricate the turntable of the arm with a small amount of white lithium grease.

Place the grease around the Large Turntable Internal Ring. This should ensure that movements are more fluid.

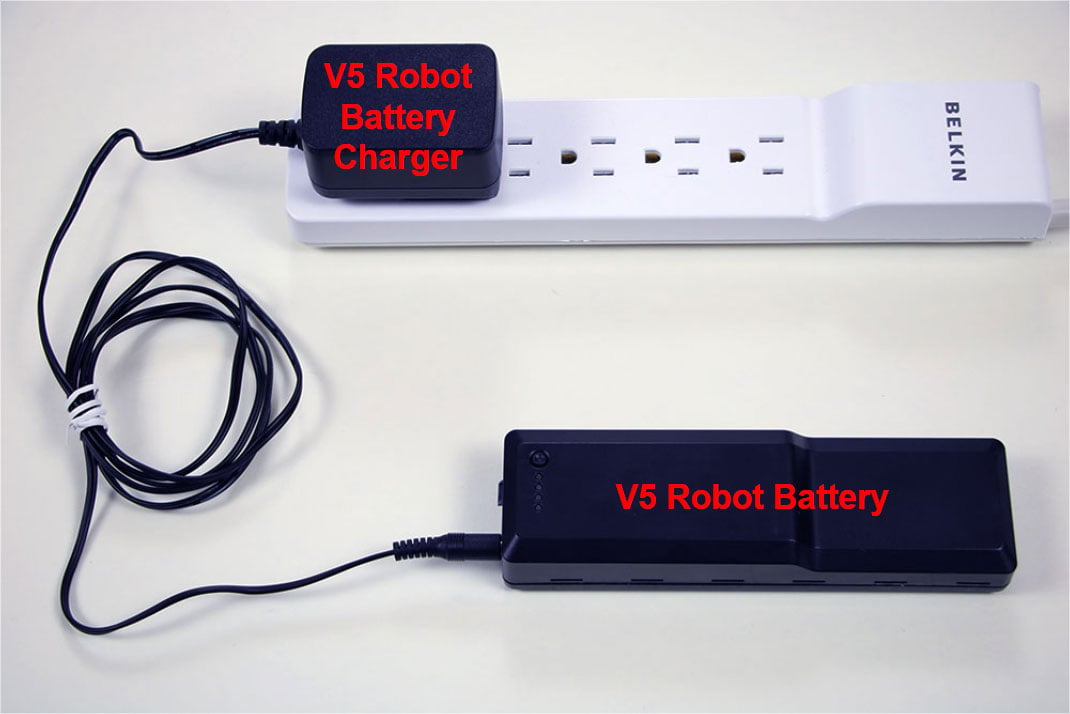

Ensure the battery is charged

While working with the Workcell, it is important to ensure that the V5 Battery is fully charged.

This will ensure that the arm on the Workcell will work as intended.

In later Labs, when multiple motors and sensors are added to the Workcell, the V5 Battery may lose charge faster, due to the amount of devices that it is supporting.

To ensure that the V5 Battery is working properly, charge the battery before use.

You can also continue to use the V5 Battery as it is charging by keeping the V5 Battery plugged in to a power source while the V5 Battery is in use.

For more information about the V5 Battery, view the following articles from the Knowledge Base: