Industrial Robotic Safety

![]() Teacher Toolbox

-

Introducing the Industrial Robotic Safety page

Teacher Toolbox

-

Introducing the Industrial Robotic Safety page

Introduce the Play reading to your students. Through this reading, they will be:

-

Identifying what an emergency stop is and when to use it.

-

Identifying that the Bumper Switch on the Workcell simulates an emergency stop.

-

Identifying what pinch points are, and where they are found on the Workcell.

For information on how to facilitate this page, go to the V5 Educator Certification.

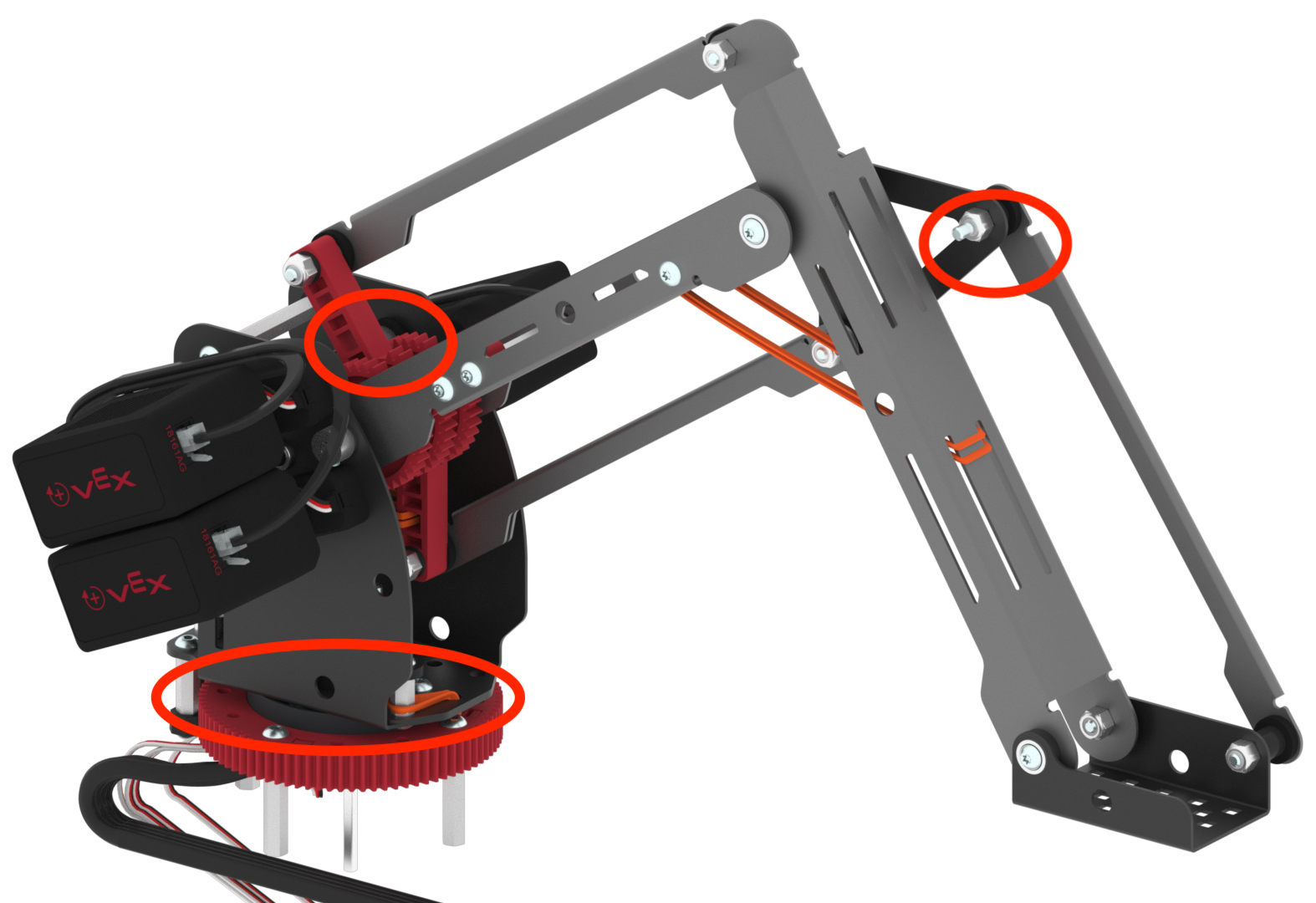

Pinch Points

When assembling, coding, or interacting with robots at any time, it is important to ensure proper safety interactions. Whenever a robot moves, it has the potential of creating a pinch point. Pinch points occur wherever a moving object comes in contact with another object. On the V5 Workcell, pinch points can occur near gears, the turntable, and on the moving arm. Three out of the many possible pinch points on the Workcell are shown in this image below.

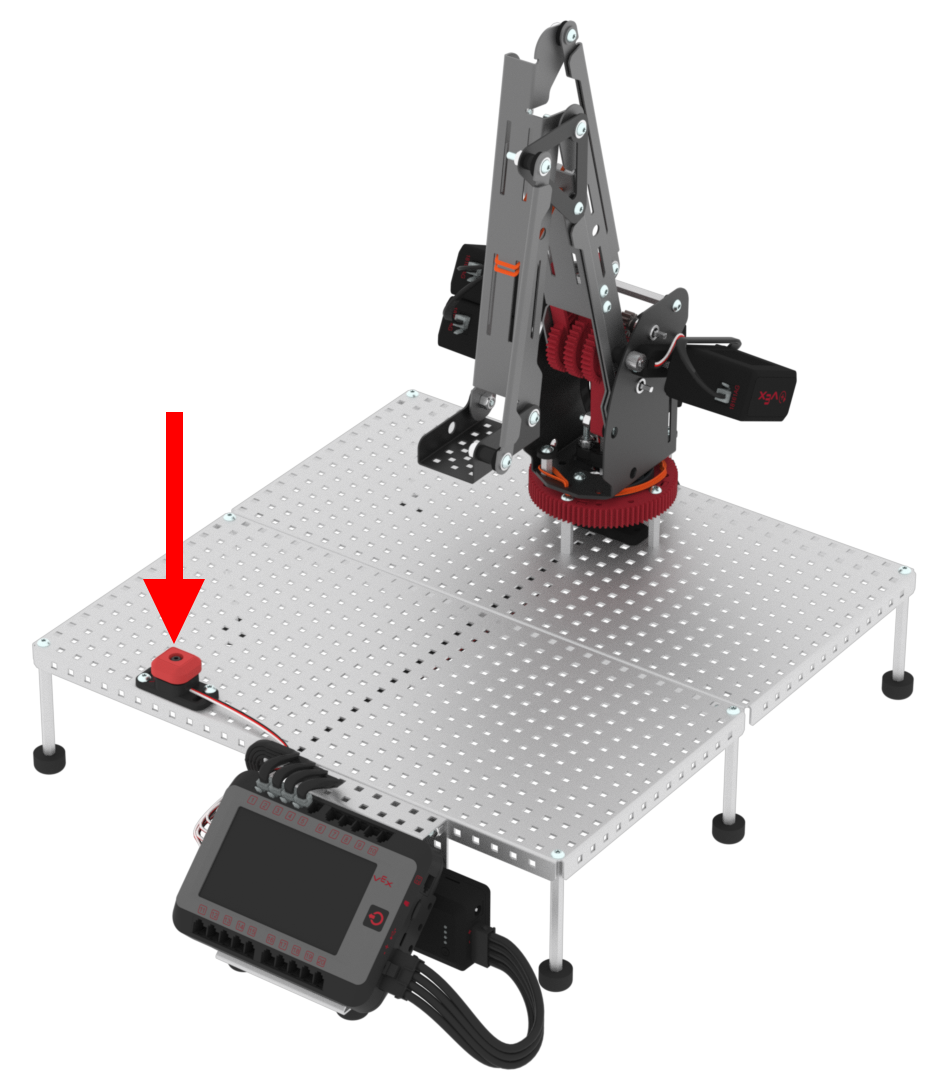

Emergency Stops

Safety precautions are measures that are put in place to protect workers and prevent accidents and injuries. Emergency stops, also known as E-stops, are designed to allow a worker to shut down a piece of equipment, such as a robot, quickly and efficiently. The E-stop might be activated if the equipment is malfunctioning, if a fellow worker is being injured by the equipment, or because of some other hazard, such as a fire.

For the Workcell, a Bumper Switch will be used to simulate an E-stop. The Bumper Switch can be pressed if the Workcell is moving in a way that is damaging to itself, or the user. Pressing the Bumper Switch will immediately stop the VEXcode V5 project and all the motors on the Workcell. The E-stop can only be used to shut down the Workcell when coded to do so in VEXcode V5. The Play section of this Lab will walk you through how to code the Bumper Switch to simulate an E-stop on the Workcell.

Important

An emergency stop or E-stop button/feature is used to ensure the safety of workers as well as the machinery. An E-stop will act as a fail-safe if the machine's functioning becomes a hazard to individuals, other machinery, or itself. A proper safety-regulated E-stop does not only shut down equipment, but also provides a guaranteed equipment shutdown and stops all hazardous mechanical motion.

For the V5 Workcell and throughout every STEM Lab, the Bumper Switch added in the Workcell is not a proper safety-rated E-stop and provides only a simulation of the functionality of an E-stop. The Bumper Switch's software 'E-stop' functionality will act more like a 'Control Stop' feature to halt a running VEXcode V5 project and shut off any V5 Smart Motors and Sensors connected to the V5 Brain.