Preview

- Grade(s): 9-12

- Time: 1.5 weeks

Description

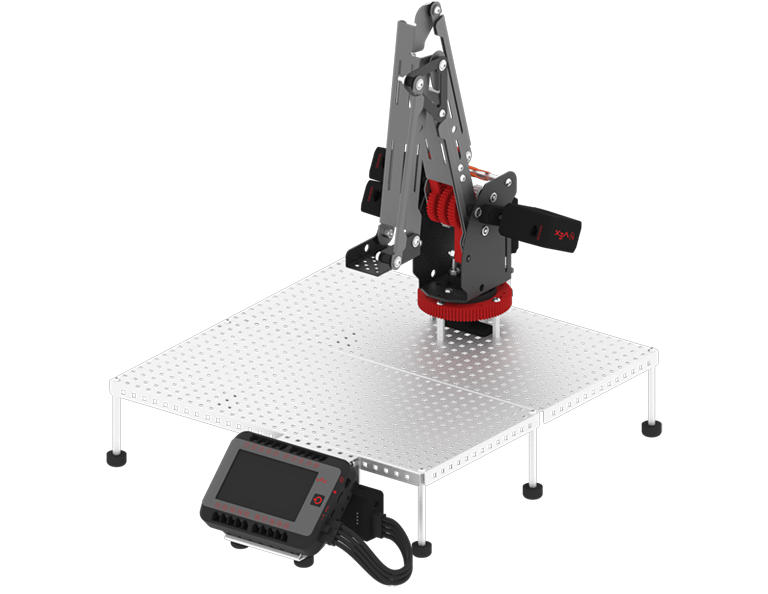

Students will be introduced to the area of Industrial Robotics, its components, and real world applications by first building the VEX V5 Workcell. Students will then learn how to check and update its firmware and run an example project to find mastering values. Students will also explore the four types of automation and the five types of facilities where they are found. After the students have explored these concepts, they will take a survey to inventory their attitudes about robotics, to keep as a reference to see how their attitudes may change throughout the course.

Essential Question(s)

- What is an industrial robot, and how can it be used in manufacturing?

- Why is it important to have an understanding of industrial robotics facilities for today’s manufacturing workforce?

Understanding(s)

Students will understand:

- What are Industrial Robots, and their four main components, applications, and facilities?

Objective(s)

- Follow building instructions to build the V5 Workcell.

- Explain what an industrial robot is.

- Identify that the four main components of an industrial robot are: manipulator, power supply, controller, and teach pendant.

- Describe applications of industrial robotics such as welding, assembly, painting, and sorting.

- Describe the four automation types: Mechanization, Fixed/Hard Automation, Programmable Automation, and Flexible Manufacturing Systems.

- Describe the five facility types: process layout, product layout (Assembly Line), fixed layout, work-cells, and combined layouts.

Vocabulary

- Industrial Robot

- A programmable multifunctional, manipulator used in manufacturing and similar environments.

- Manipulator

- A physical robot arm.

- Actuator

- A component which causes motion. It requires a force to move an object. An actuator provides the force to allow a robot to activate an action. Industrial Robotics use electrical, pneumatic, and hydraulic actuators.

- Power Supply

- The source of energy for the robotics system. This is usually electrical energy.

- Controller

- This is considered the “Brain” of the robotics system. It controls the outputs and the behavior of the robot based on the condition of its inputs and program.

- Teach Pendant/ Human Interface Device

- A device which allows humans to interact directly and program the robot’s controller.

- Mechanization

- Mechanization is any type of machine-assisted production. Historically this was the first type of automation used in manufacturing. (example: equipment used in a woodworking shop)

- Fixed/Hard Automation

- These systems are used in high volume production to carry out a repetitive specific function. (example: equipment used in a firewood processing plant)

- Programmable Automation

- This type of automation allows for changeable functions within a production system. With this type of automation, the production sequence is not changed automatically or very often so It can use lower cost electronic controls. (example: equipment used in an automated metal castings plant)

- Flexible Manufacturing Systems

- These systems are computer controlled from high-level computer code. This type of production can be changed and the type of production process is changed automatically. The loading and unloading of tools is controlled by the computer code, as well as, the automated passing of products from one process to the next. (example: equipment used in an automated vehicle factory)

- Process Layout

- With this type of facility, the floor is laid out in specific departments with specific functions, such as a specific department for cutting or shaping objects. The product is carried back and forth between departments as functions are needed to be performed on it. (example: custom furniture shop)

- Product Layout (Assembly Line)

- In this type of facility the product flows through a series of processes. The layout of the processes is determined by the sequence necessary to produce the product. (example: lighting fixture assembly plant)

- Fixed Layout

- This type of layout does not have the product moving. The product is too large, bulky, or fragile to move. The supplies, tools, and personnel are brought to the product. (example: naval shipyard)

Materials Needed

| Quantity | Materials Needed |

|---|---|

| 1 |

V5 Workcell |

| 1 |

Build Instructions |

| 1 |

VEXcode V5 |

| 1 |

Engineering Notebook |

| 1 |

Device to run VEXcode V5 |

| 1 |

Micro-USB cable |

| 1 |

Mastering Jig |

Educational Standard(s)

- Next Generation Science Standards (NGSS) HS-ETS1-3: Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics as well as possible social, cultural, and environmental impacts.

- International Society for Technology in Education (ISTE) 4a: Students know and use a deliberate design process for generating ideas, testing theories, creating innovative artifacts or solving authentic problems.

- International Society for Technology in Education (ISTE) 4d: Students exhibit a tolerance for ambiguity, perseverance and the capacity to work with open-ended problems.

- Common Core State State Standards CCSS.ELA-LITERACY.W.11-12.2.E: Establish and maintain a formal style and objective tone while attending to the norms and conventions of the discipline in which they are writing.

- Standards for Technological Literacy (STL) 2.X: Systems, which are the building blocks of technology, are embedded within larger technological, social, and environmental systems.

Go to this page in the Knowledge Base to see a cumulative list of VEX V5 Workcell STEM Labs standards.