Preview

- Grade(s): 9-12

- Time: 4 weeks

Description

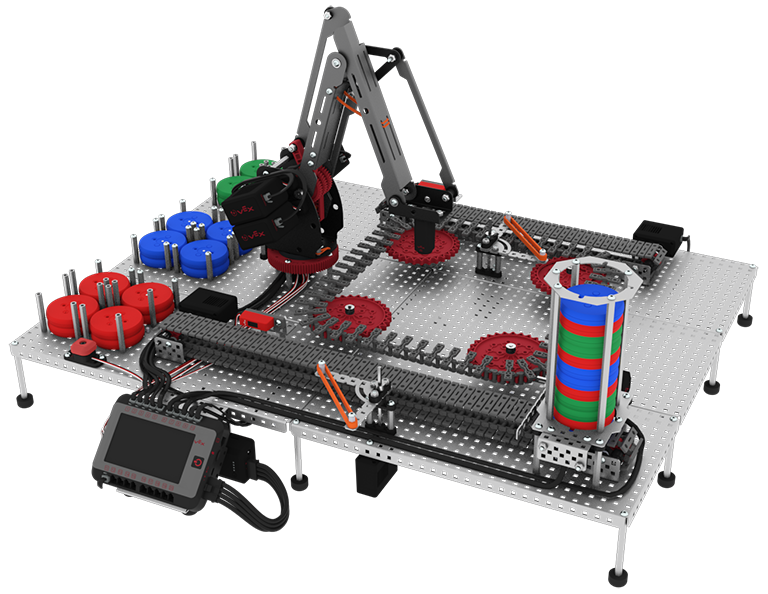

Students will be guided through understanding the mechanical limits of the arm on the V5 Workcell and how to use that information while planning the layout of their Workcell. They will also learn about how to determine the coordinate system of a Workcell with a moved arm, technical information about moving the arm, and steps to create their own custom V5 Smart cables. After they have learned these techniques, they will be challenged with the Capstone Project Competition. This competition challenges students to sort 36 disks as quickly as possible into the matching colored End Zone. They will need to apply all that they have learned in Labs 1-12, the Workcell Extensions, and Lab 13 to compete.

Essential Question(s)

- How do I design and build a custom Workcell for a competition?

- How do I prepare for the Capstone Project Competition?

Understanding(s)

Students will understand:

- How to design a new Workcell layout for the Capstone Project Competition.

- How to build and test the new layout of the Workcell system using the Engineering Design Process.

- How to compete in the Capstone Project Competition.

Objective(s)

- Identify that a mechanical limit is the point at which the linkages in a system should move no further to avoid strain or potential damage.

- Identify that the V5 Workcell arm has a dead zone of 75 degrees due to the Potentiometer on Joint 1.

- Identify that the coordinate system of the Workcell is determined by the orientation of the Potentiometer at the center of the turntable (Joint 1).

- Identify the steps needed to move the arm on the Workcell from one location to another.

- Identify that custom V5 Smart Cables are made to help with efficient cable management.

- Identify the steps needed to create a custom V5 Smart Cable.

- Identify the rules of the Capstone Project Competition.

- Identify that the Engineering Design Process is an iterative process made up of three steps: define, develop solutions, and optimize.

Vocabulary

- Cartesian Coordinate System (in 3D space)

- A system based on three mutually perpendicular coordinate axes: the x-axis, the y-axis, and the z-axis. All three axes intersect at the point called the origin (0, 0, 0)

- Mechanical limit

- The point at which the linkages in a system should move no further to avoid strain or potential damage

- Orientation

- The physical position or direction of an object relative to other objects in its surroundings

Materials Needed

| Quantity | Materials Needed |

|---|---|

| 1 per group |

V5 Workcell |

| 1 per group |

VEXcode V5 |

| 1 per group |

Engineering Notebook |

| 1 per group |

Device to run VEXcode V5 |

| 1 per group |

Micro-USB cables |

| 36 per group |

Colored Disks (12x red, 12x green, 12x blue) |

| 1 per group | |

| 1 per group |

V5 Smart Cable Crimping Tool |

| 1 length per group |

V5 Smart Cable Stock |

| 2 per custom cable |

V5 Smart Cable Connectors |

| 1 per group |

Marker (or other writing utensil) |

| 1 per group |

Length of string (optional) |

| 1 per group |

Printable VEX V5 Ruler (optional) |

Educational Standard(s)

- Next Generation Science Standards: HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering.

- Computer Science Teacher Association: 3A-AP-13 Create prototypes that use algorithms to solve computational problems by leveraging prior student knowledge and personal interests.

- Computer Science Teacher Association: 3A-AP-18 Create artifacts by using procedures within a program, combinations of data and procedures, or independent but interrelated programs.

- Computer Science Teacher Association: 3A-AP-17 Decompose problems into smaller components through systematic analysis, using constructs such as procedures, modules, and/or objects.

- Standards for Technological and Engineering Literacy: STEL-7Y Optimize a design by addressing desired qualities within criteria and constraints.

- Standards for Technological and Engineering Literacy: STEL-7BB Implement the best possible solution to a design.

- Standards for Technological and Engineering Literacy: STEL-7CC Apply a broad range of design skills to their design process.

Go to this page in the VEX Library to see a cumulative list of VEX V5 Workcell STEM Lab standards.