Actuators in Everyday Objects and Industrial Robots

In 1686, Sir Isaac Newton wrote that an object will not change its state of motion unless a force is applied upon it. This is still true today. A robot can not move without a force. This force comes from a device called an actuator or a device that causes an action.

Types of Actuators

- Hydraulics

- Pneumatics

- Electrical Motors: Stepper Motors, and Servo Motors

There are many everyday devices that make things move. Some of these devices are the same things that make industrial robots move. They may not look the same, but they work on the same principles.

Hydraulics

When observing a garbage truck dumping a dumpster, large cylinders can be observed with shafts extending out of them, lifting the dumpster. These are hydraulic cylinders.

Hydraulics actuators use a pump to pressurize hydraulic fluid. Valves release the fluid through hydraulic hoses. The pressure in the hoses can cause the shaft of a hydraulic cylinder to move out or move in. The pressure in the hoses can also cause the shaft of a rotational hydraulic actuator to spin.

Hydraulics can move and hold very heavy items. A robot with a hydraulic system could be used to move very heavy loads and tools.

A robot with a hydraulic system could also apply a great deal of force.

Hydraulic cylinders are very useful when a linear motion (moving in a line) is needed.

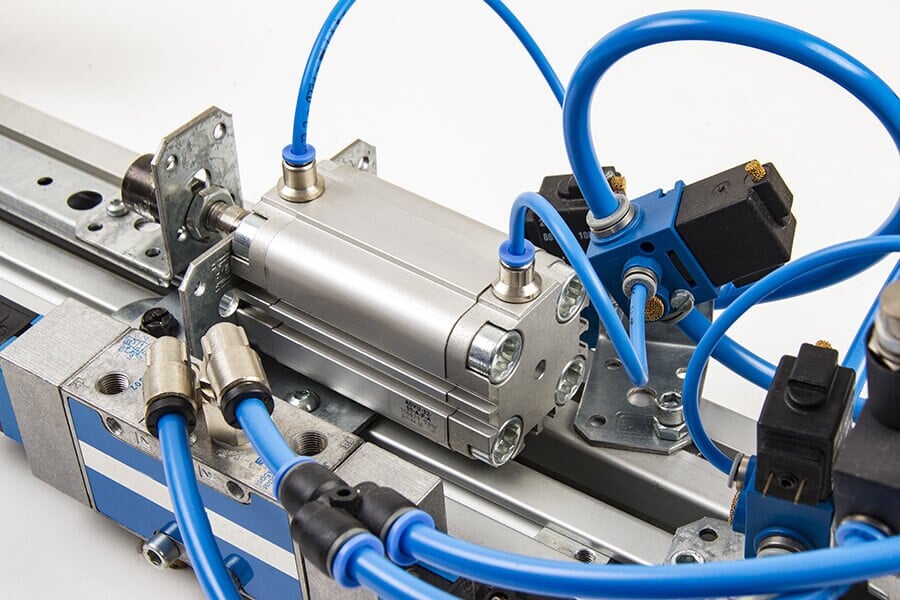

Pneumatics

Other types of actuators that are very similar to hydraulics are called pneumatics. The major difference between these two types of actuators is that pneumatics use air instead of hydraulic fluid. Imagine a balloon. As air pressure blows into the balloon, it extends out.

If air is let out of the balloon, it flows out very quickly. This can also happen with pneumatic actuators because activated air can move fast. Pneumatic cylinders are also useful when linear motion is needed.

A pneumatic actuator uses an air compressor to pressurize air.

Valves release the air pressure through pneumatic tubing.

The air pressure in the tubing can cause the shaft of a pneumatic cylinder to move out or move in.

The pressure in the pneumatic tubing can also cause the shaft of a pneumatic rotary actuator to spin.

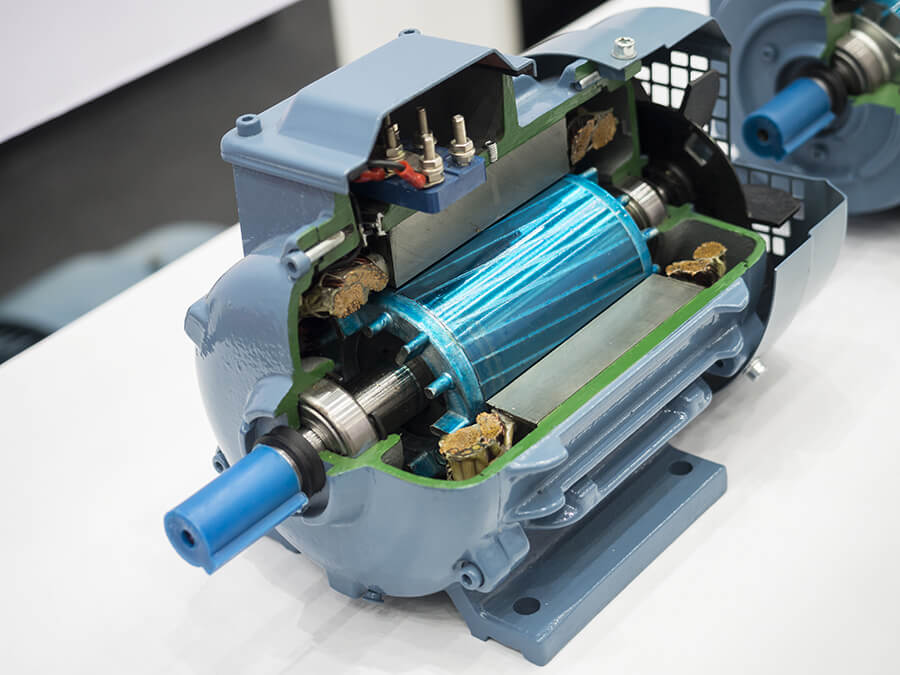

Electric motor

Washing machines, clothes dryers, vacuum cleaners, and food processors are some examples of household appliances that work because they have an electric motor.

Electric motors are actuators that convert electrical energy into rotational mechanical energy that causes a shaft to spin.

There are electric motors that are powered by Direct Current (DC), such as the motor in a cordless drill.

Electric motors can also be powered by Alternating Current (AC), such as all of the household appliances listed above.

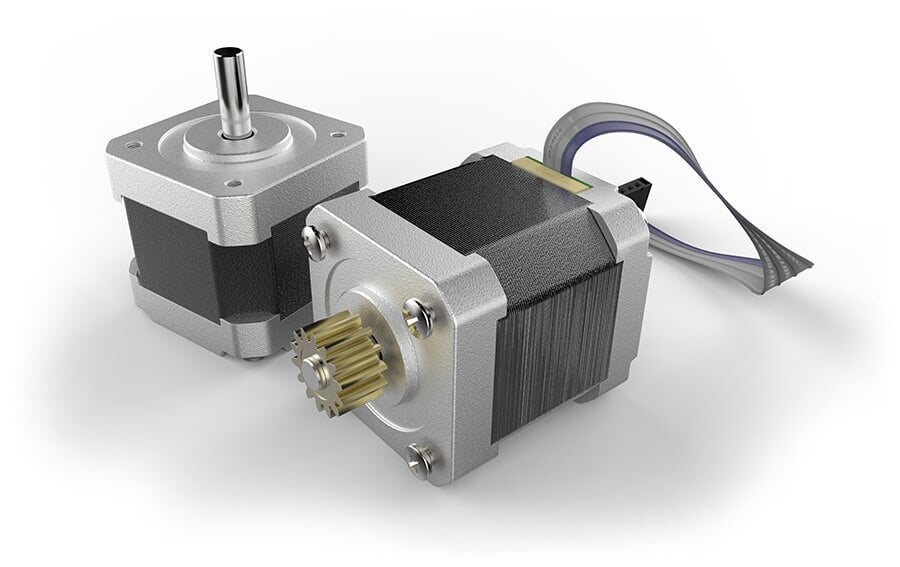

Stepper motor

Nearly all industrial robots have electric motors for at least some of their actuators. Most of these motors have additional controls to help the robot move. Two special types of electric motors that are found on industrial robots are stepper motors and servo motors.

A stepper motor uses Direct Current (DC), and the rotation of its shaft is divided into a number of equal steps for better control of the movement of the shaft.

Look closely at the motion of the second hand on an electric clock, it steps forward 60 steps every rotation.

This is because the clock uses a stepper motor which precisely controls the clock’s second hand.

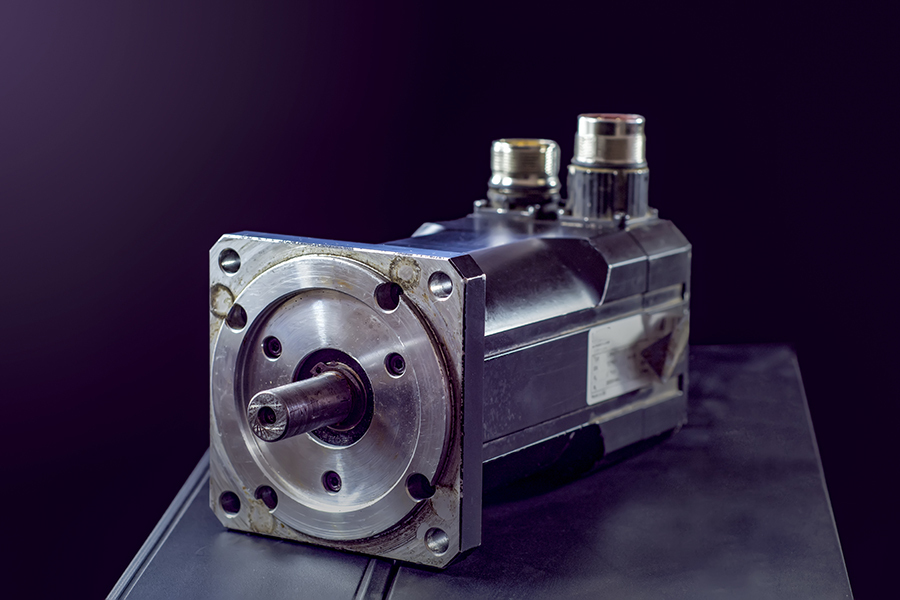

Servo motor

A servo motor has a sensor/sensors which can be used to control things like position, speed, and acceleration of its shaft.

Many toy remote control cars use servo motors to control their steering.

The sensors in the motor allow the motor to precisely control how much the toy car's steering linkages are moved.