Robot Movement and Robot Configurations

There are some movements that humans are unable to do. For instance, it is impossible for a person to scratch the top of their right wrist with their right hand. Their joints do not allow them to move that way. Industrial robots have the same types of limitations.

There are certain factors which define a robot’s movement. These factors are considered when selecting a robot. Most industrial robot designs fall into one of the six common robot configurations: Cartesian, Cylindrical, Spherical, Selective Compliance Articulated Robot Arm (SCARA), Articulated, and Delta (Parallel).

Robot Movements

Whenever an object moves, its possible movements are:

- Forward / backward

- Side to side

- Upward / downward

- Rotate

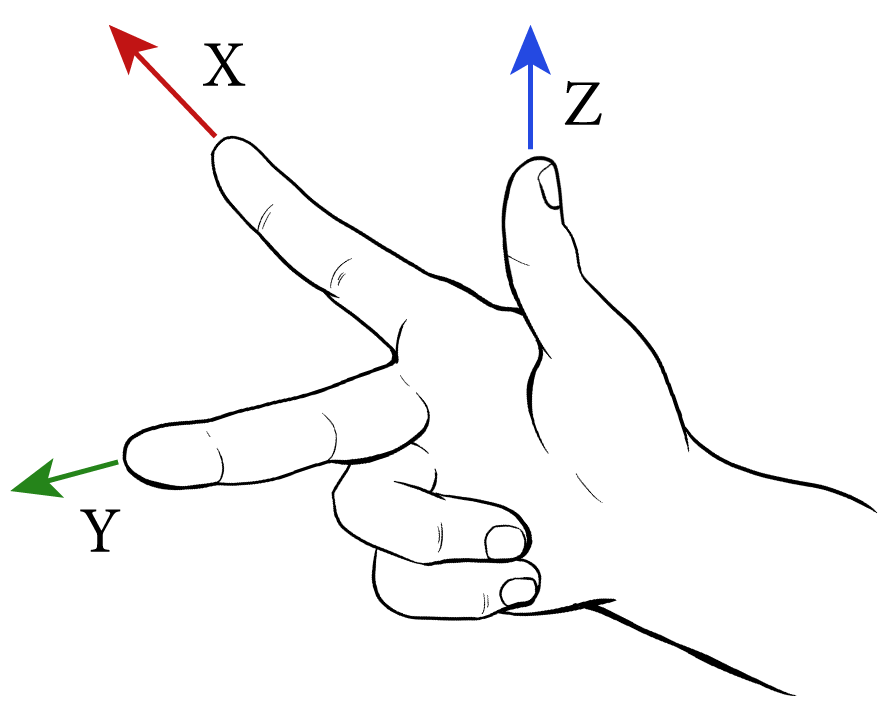

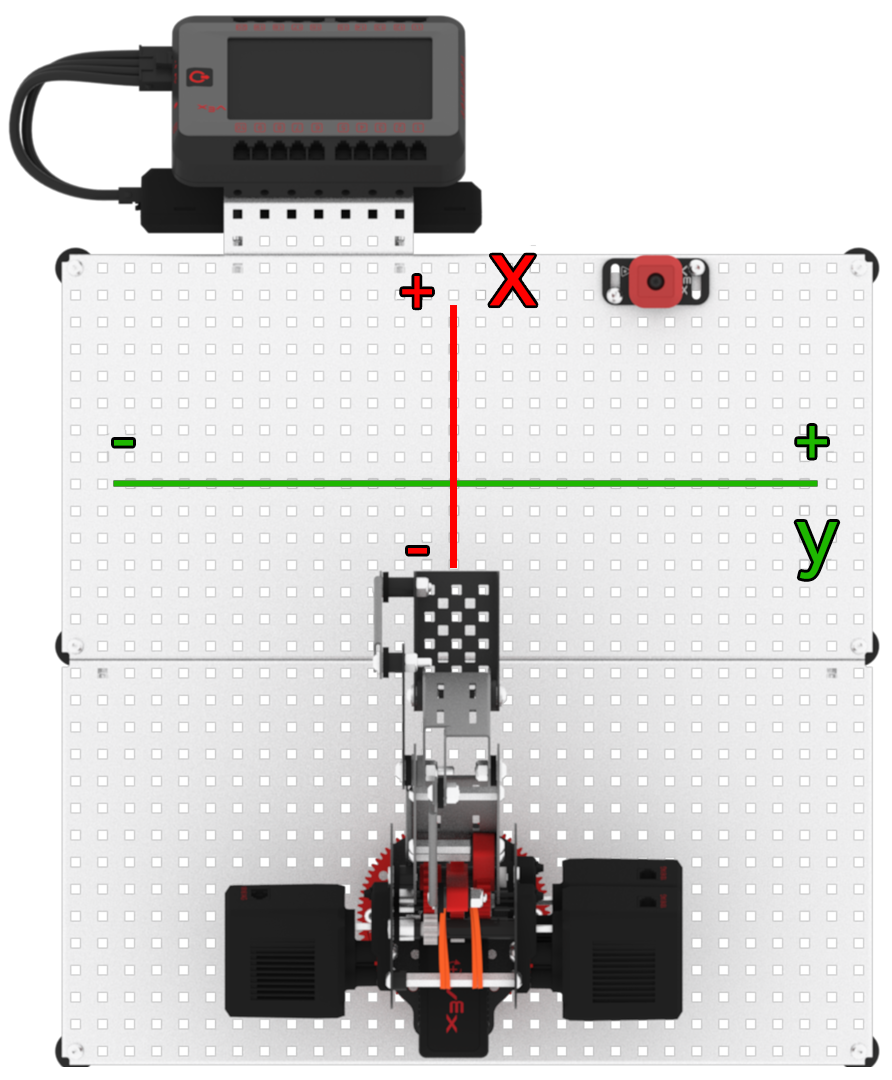

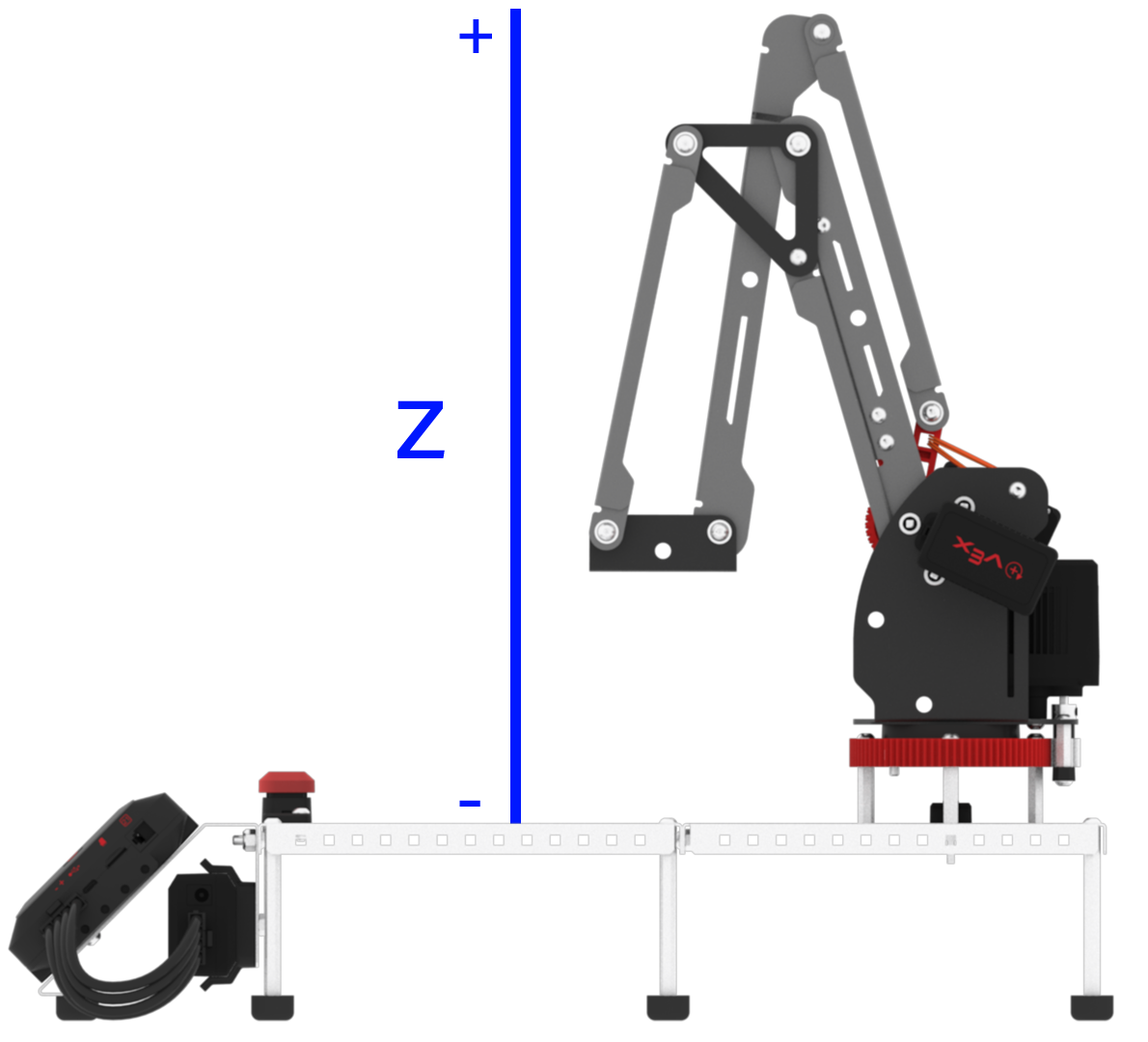

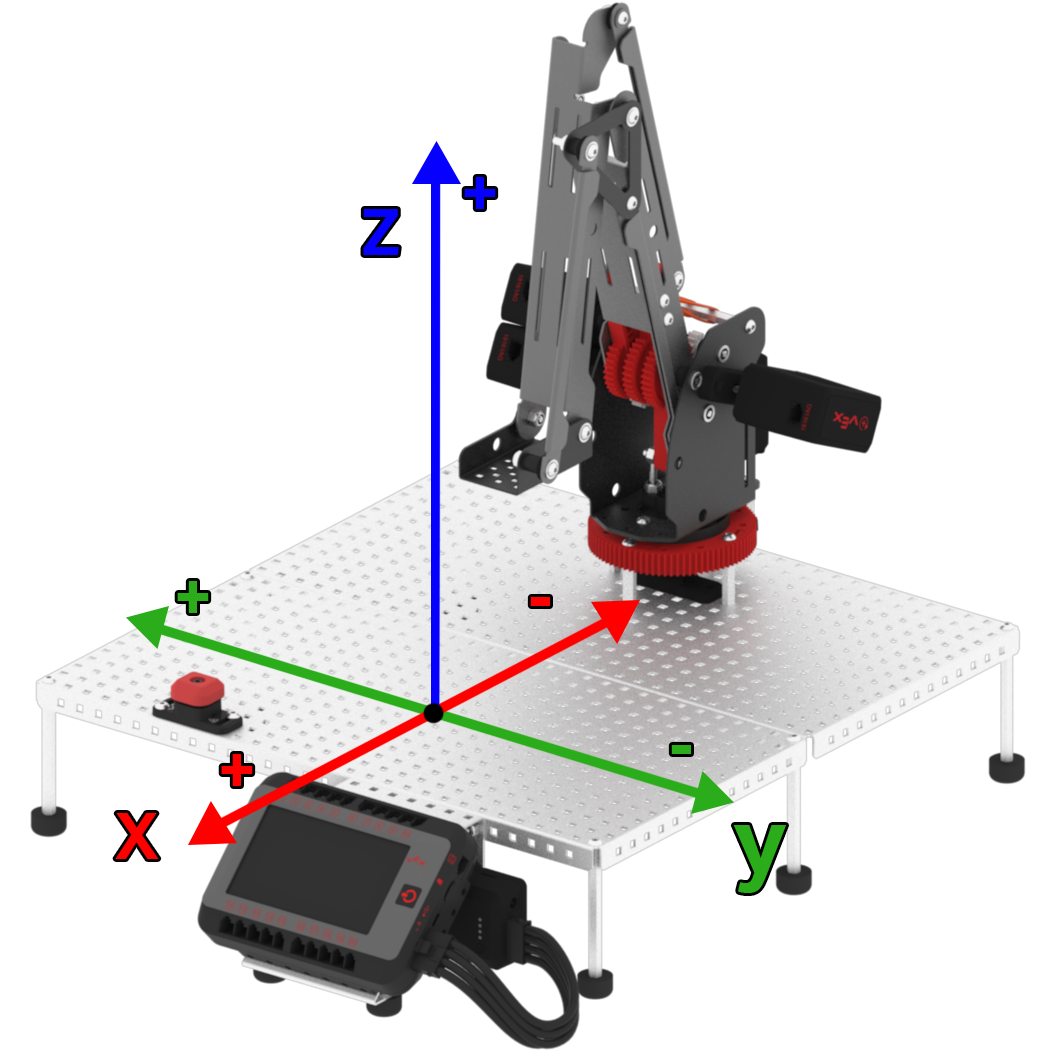

These movements happen in what is commonly described as three dimensional space. This space is typically placed on a Cartesian coordinate system which is divided up and measured by 3 axes or lines in space. The x, y, z axes that the arm mounted on the VEX V5 Workcell move on follow the “right-hand rule.”

The x-axis spans forward to back from the robot base. The y-axis spans from left to right.

The z-axis spans vertically up/down.

All motion can be defined as linear motion (back and forth) and/or rotational motion, either along the axes or between the axes. These are the axes of motion, sometimes referred to as the degrees of freedom (DoF) of movement.

For example, the turntable on the base of the arm mounted on the V5 Workcell rotates around the arm’s z-axis giving it one degree of freedom. The turntable is attached to the platform, so it can not move front to back or side to side. The turntable is limited in those axes of motion and has no degrees of freedom of movement in those directions.

The V5 Workcell’s shoulder allows the arm to rotate about its x-axis giving it a second axis of motion. The arm’s elbow also rotates around its x-axis giving it a third axis, and the wrist rotates around its x-axis giving it a fourth axis of motion. The arm mounted on the V5 Workcell has four axes of motion, or, it could be said, four degrees of freedom. These four axes of motion will allow the arm to move a tool placed on the wrist/tool plate to any x, y, z coordinate within its workspace.

Axes on an industrial robot can be divided into major axes and minor axes. The major axes deal with the position of the robot’s wrist. The minor axes position the robot’s tool. The arm mounted on the V5 Workcell has three major axes to position the wrist and one minor axis for its tool.

The minor axes used to position the robot’s tool have some additional terms to describe the tool’s rotational movement. These include: yaw, pitch, and roll. Yaw refers to the rotation around the tool’s up and down axis, pitch is the rotation around the side to side axis, and roll is rotation around the tool’s front to back axis. Any tool placed on the arm mounted on the V5 Workcell will only have a pitch movement because it lacks axes in the two other directions.