Arm Mechanical Limits

| Quantity | Materials Needed |

|---|---|

| 1 per group |

V5 Workcell |

| 1 per group | |

| 1 per group |

Engineering Notebook |

| 1 per group |

Device to run VEXcode V5 |

| 1 per group |

Micro-USB cable |

| 1 per group |

In this section, you will be introduced to different concepts that will prepare you to design your own Workcell for the Capstone Project Competition.

You will learn about Workcell design by analyzing why the build in Lab 11 is laid out in a specific way. By going through and understanding the design of the Lab, you will learn about concepts such as the Workcell arm’s mechanical limits, how and why conveyors are placed in certain locations, and the importance of pick up and drop off locations. These concepts can be applied when you design your own Workcell in the Rethink section.

Throughout the Play section, you will also explore how moving the location of the arm affects its X, Y, and Z-coordinates, how to mechanically move the location of the arm on the Workcell, and the option to create custom V5 Smart Cables.

First, you will explore the arm’s mechanical limits and why this information is important when considering how to lay out your Workcell. A mechanical limit is the point at which the linkages in a system should move no further to avoid strain or potential damage. Understanding the mechanical limits of the arm will help you answer questions about the flow of disks.

- Where will the disks be picked up?

- Can the arm reach the disks on the conveyor?

- Where will the disks be dropped off?

- Can the arm physically reach the drop off location(s)?

Arm Mechanical Limits

The V5 Workcell’s arm has mechanical limits. This means that the arm itself can only extend so far. Overextending the arm could result in damage.

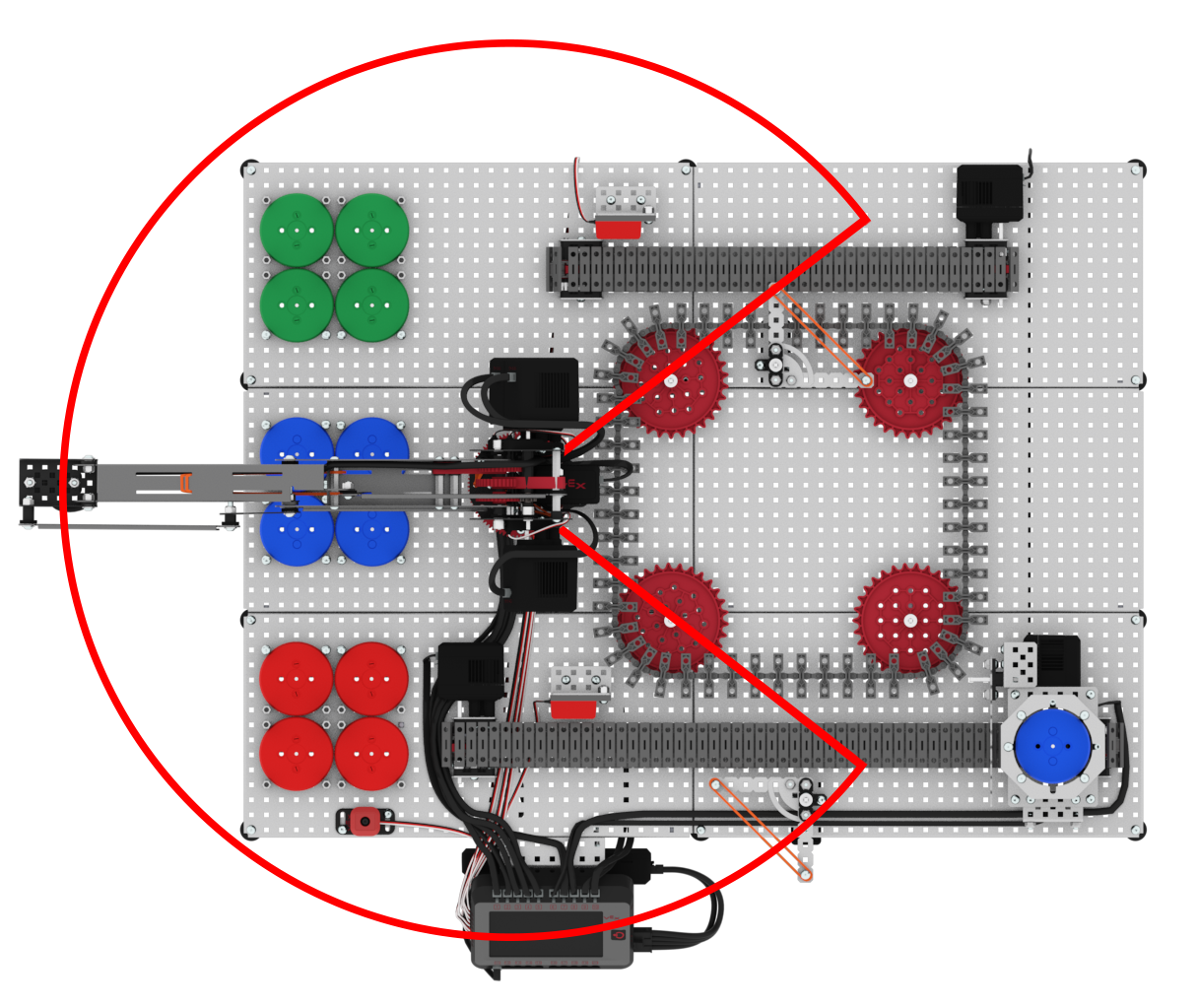

The image on the left shows the maximum range of the arm, fully extended without any end effectors (such as the marker attachment or the Electromagnet). Without any end effectors on the arm, the max reach is 13.87 inches.

Adding certain end effectors like the marker attachment or Electromagnet will decrease the max reach, as adding an end effector will adjust the z-axis of the arm, causing it to not extend as far.

For more information about the Workcell’s dimensions, view this article.

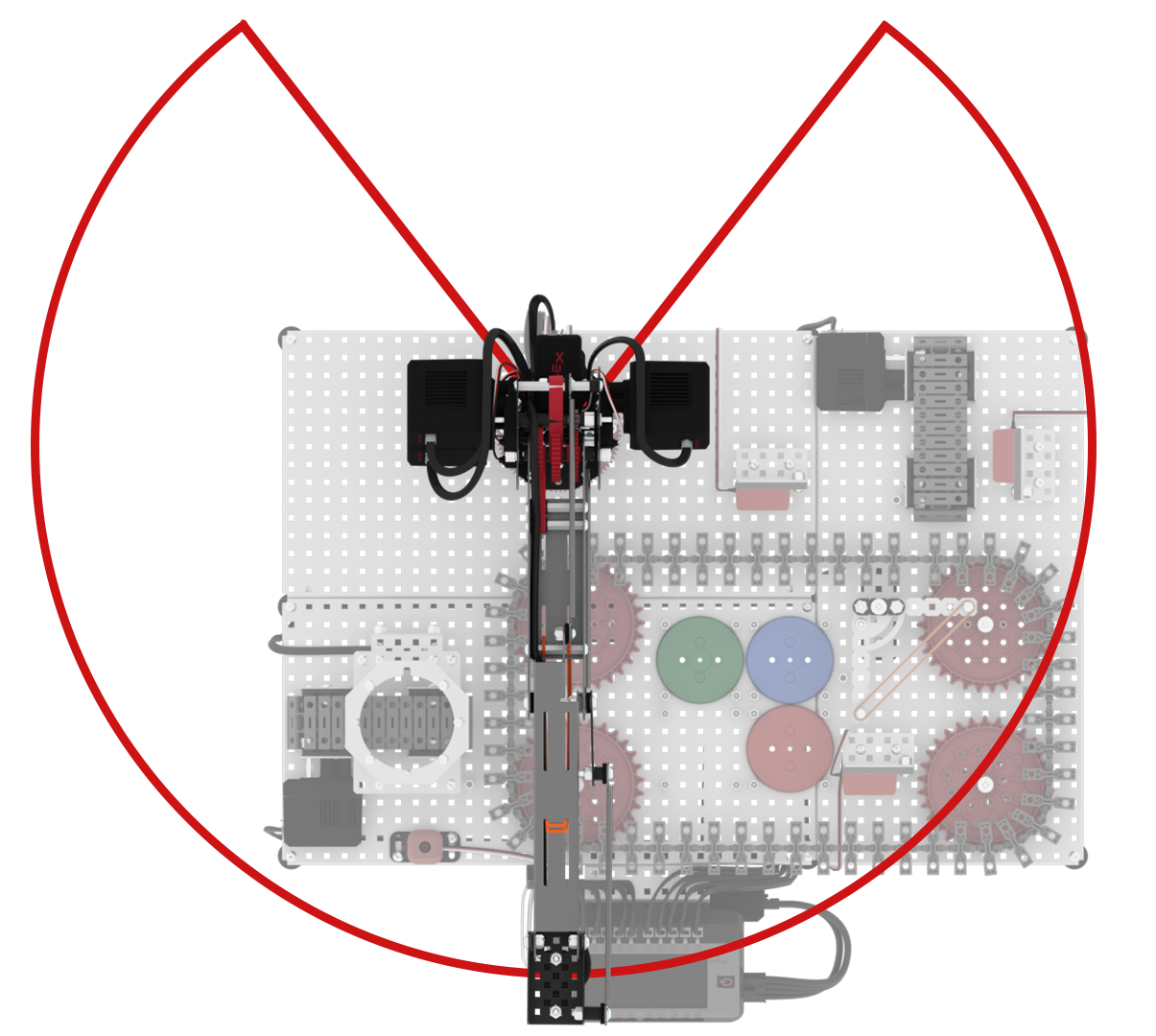

Notice that there is a dead zone behind the arm. Due to the potentiometer used with Joint 1 (connected under the turntable), there is a dead zone behind the arm of 75 degrees. This means that the arm can only rotate so far in the left and right directions.

This is important to keep in mind when determining where to place the arm on the Workcell. For example, I would not place a pick up location for disks directly behind the arm, because it will not be able to turn 360 degrees to reach it.

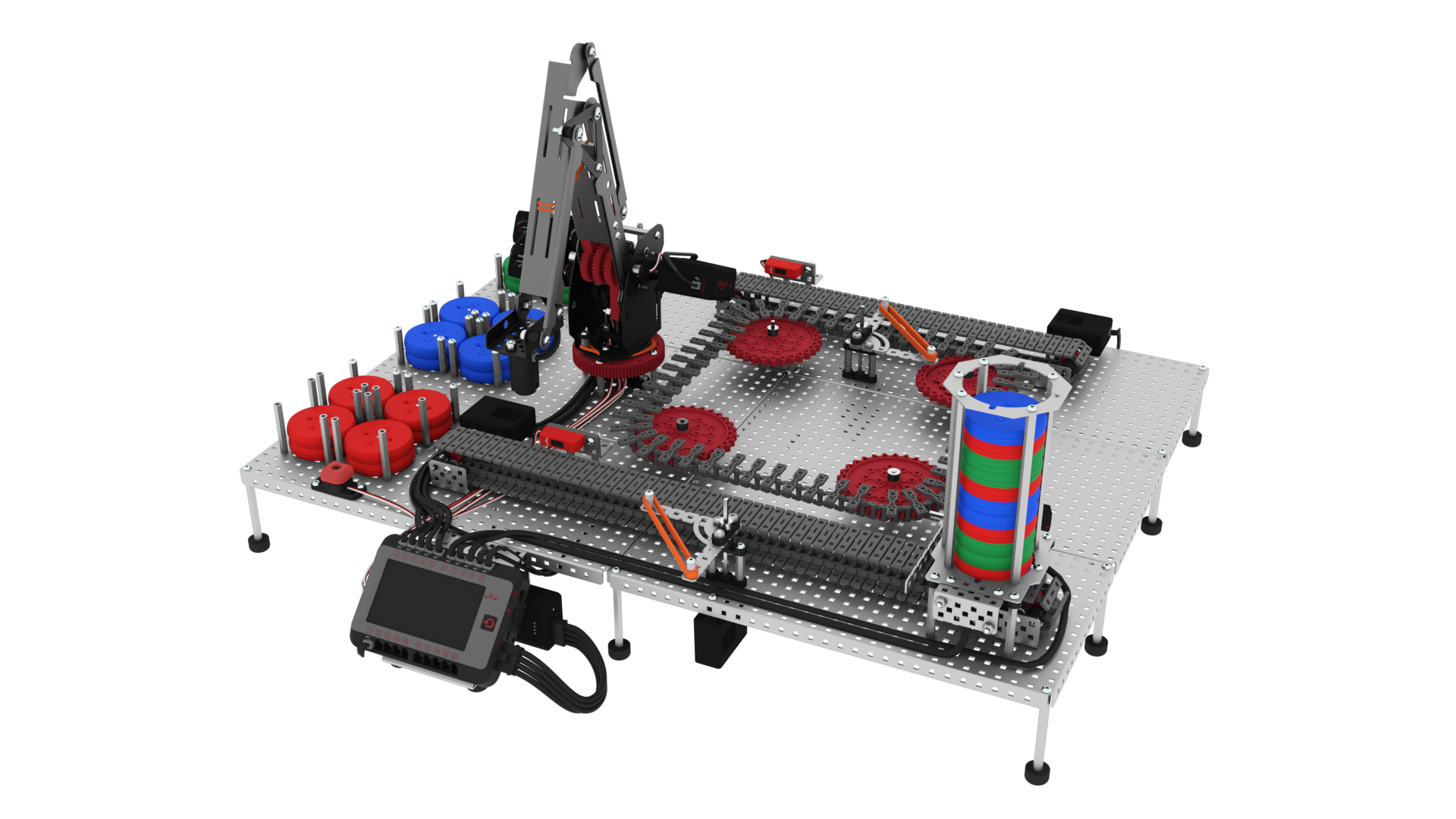

Viewing an example Lab 13 build, notice how the arm is mounted facing the V5 Brain. This allows the arm to rotate to either side, picking up and placing disks from the conveyors, or moving them to the End Zone locations.

Understanding the Layout of a Build

The Lab 11 build shown here is designed in order for the arm to be able to extend and reach certain points using the arm’s end effector. This design considers the mounting placement of the arm that affects important locations for the arm to reach:

- Pick up location

- Drop off locations

In Lab 11, the arm’s task is to pick up the disk from the Transport Conveyor, and place it in the appropriate drop off location based on the color of the disk.

Note that the arm will not be able to reach the entirety of the Transport Conveyor. However, it can mechanically reach the set pick up location along the conveyor.

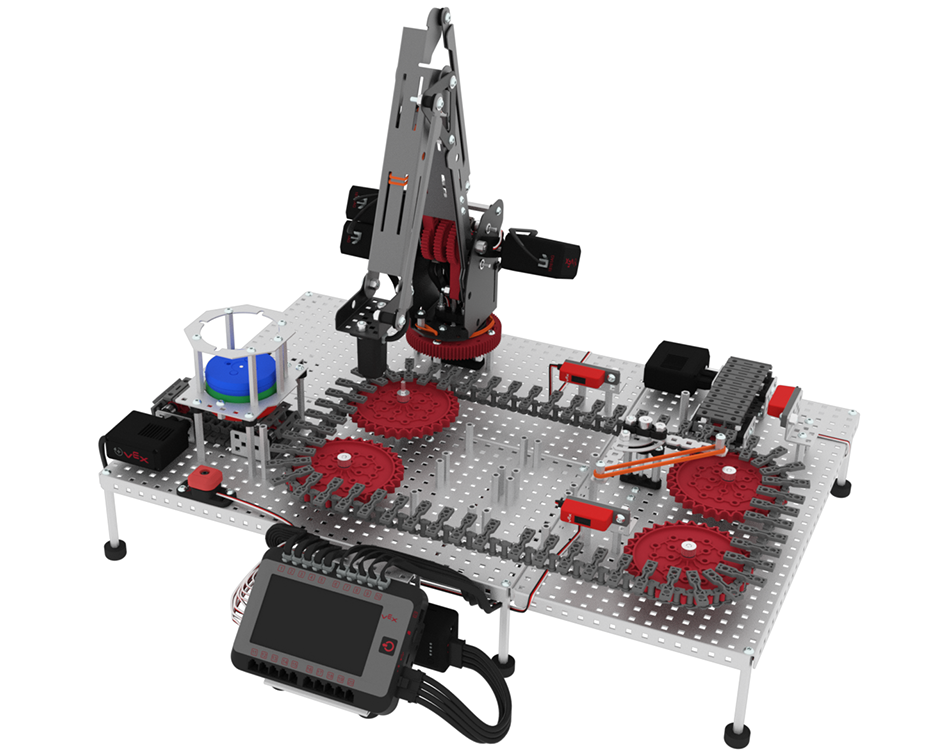

Looking at an example Lab 13 build, you can see when the arm is rotated 90 degrees, the dead zone now faces the circular conveyor.

The arm can easily reach all End Zones and the linear conveyors on the top and bottom of the Workcell.

These tradeoffs are important to consider when designing the layout of your Workcell.