Robot Mastering

![]() Teacher Toolbox

-

Introducing the Robot Mastering page

Teacher Toolbox

-

Introducing the Robot Mastering page

Introduce the Play reading to your students. Through this reading, they will be:

- Identifying what potentiometers are and how they function.

- Using mastering values so the Workcell knows its 'home location.'

For information on how to facilitate this page, go to the V5 Educator Certification.

| Quantity | Materials Needed |

|---|---|

| 1 per group |

V5 Workcell |

| 1 per group | |

| 1 per group |

Engineering Notebook |

| 1 per group |

Device to run VEXcode V5 |

| 1 per group |

Micro-USB cable |

![]() Teacher Tips

Teacher Tips

- Ensure the V5 Battery is charged before beginning.

- Point students to the VEX Robotics Knowledge Base if they have further questions about VEXcode V5 or the hardware.

- Instruct students to read along with the STEM Lab and follow the steps to build and run the 'Arm Mastering' project.

Robot Mastering

In this section, you will use the ‘Arm Mastering’ example project to determine the mastering values for the V5 Workcell that will be used in all subsequent Labs. Industrial robots in general, and specifically the V5 Workcell, need to operate in a way that is safe and repeatable. To achieve this, a 'home location' is needed. A 'home location' ensures that the robot can accurately repeat the same movements, as well as operate in a way that does not cause damage. On the V5 Workcell, the motors do not have physical limits in the same way that the metal of the Workcell does. The physical V5 Workcell however, does have limits and cannot move in certain orientations. Because of this, the motors could potentially continue to spin and move, even though the Workcell itself has physical limitations, causing it to potentially break. The mastering process helps ensure that the robot has a 'home location' to start from, as well as provides a range of values so that the Workcell can operate safely.

Robot mastering at a higher level, identifies the geometrical parameters of an industrial robot, such as the relative position of the joints in the robot. The mastering process is a type of calibration that increases the positioning accuracy of the robotic arm of an industrial robot. Robot mastering is performed to set the correct positions of each axis of the robot arm, relative to the base cartesian coordinate system (x, y, z).1

Mastering Values

In order to master the V5 Workcell, first we need to know the range of acceptable values that the V5 Workcell can safely operate in. This is important, because it ensures that the Workcell has a 'home location' to start from. Obtaining and recording these values, allows the V5 Workcell to be calibrated to the same 'home location' each time it operates. This is an important piece of information that is used when coding the V5 Workcell using VEXcode V5 to ensure that it operates within its pre-determined range of motion to prevent damage.

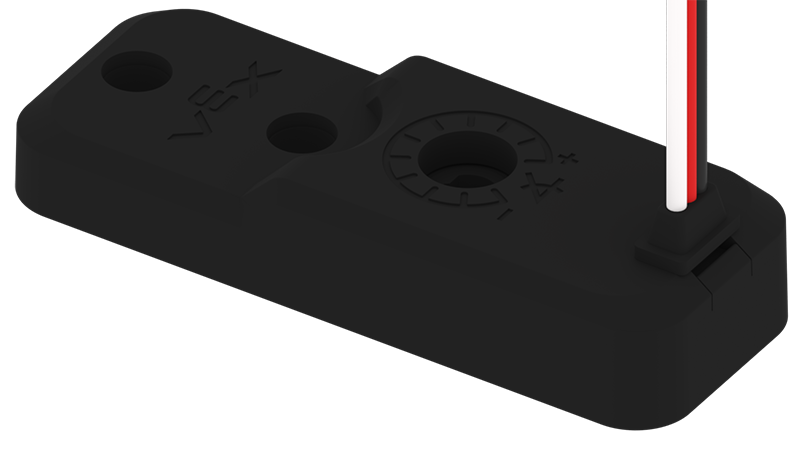

The mastering values seen in both the 'Arm Install' and 'Arm Mastering' example projects, are actually four different ranges of potentiometer values - one for each joint on the V5 Workcell. These ranges of potentiometer values are the ranges that each joint on the Workcell can operate safely in. Using potentiometers on the V5 Workcell ensures that it was built and assembled properly. The potentiometers are required to be installed at a certain position and at a certain rotation so the Workcell knows its 'home location' and functions as intended.

Potentiometers

Potentiometers are analog variable resistors, which provide a variable voltage value based on the position of the wiper arm (the piece that moves across the resistive track material) inside of the potentiometer. These are used on the Workcell to identify the position of the joints on the Workcell at all times, based on the wiper position of the potentiometer. The 3-Wire Port on the V5 Brain converts the voltage values into a digital value between 0 and 4095 and those values are displayed by using the 'Arm Install' and 'Arm Mastering' example projects.

1Mako, Peter. "Principles of Mastering at KUKA Robots." International Scientifica Journal about Machatronics 2.2 (2017): 7-12. http://actamechatronica.eu/issues/2017/II_2017_02_Mako.pdf