What are Industrial Robots?

![]() Teacher Toolbox

-

Facilitating the Apply Section

Teacher Toolbox

-

Facilitating the Apply Section

Introduce the Apply reading to your students. Through this reading, they will be:

- Making the connection between the V5 Workcell and industrial robotics.

- Exploring the four types of automation and the five types of facilities where they are found.

For information on how to facilitate the Apply section, go to the V5 Educator Certification.

What are Industrial Robots?

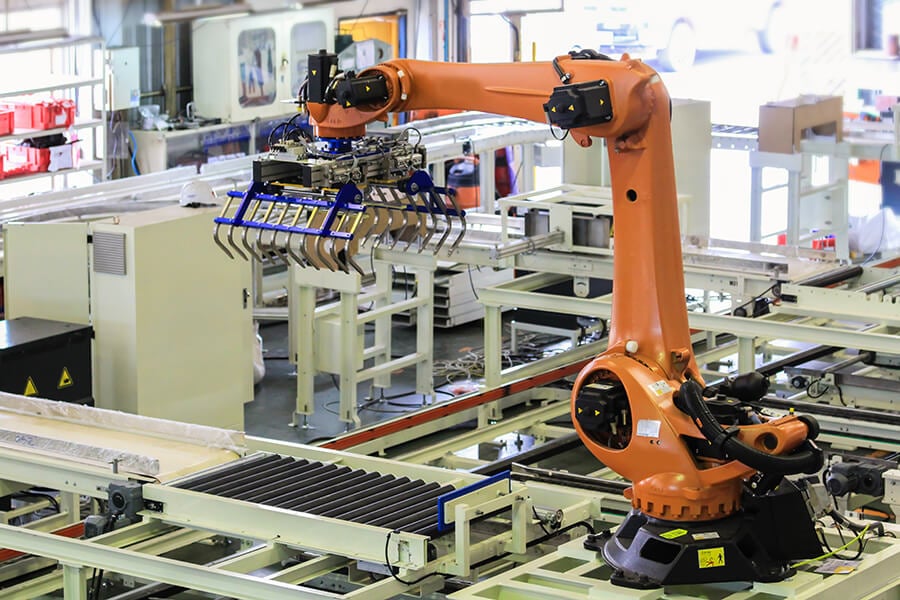

Industrial robots are robotic arms that can move in several directions and can be programmed to carry out many different types of tasks in different environments. These industrial robots can work:

- In varying environments like high-pressure and vacuum chambers.

- In clean workrooms and in terribly dirty areas.

- In dangerous areas where threats of explosions, infections, radiation, or other extreme hazards are present and dangerous to humans.

Robotic arms can be equipped with specialized grippers to work with delicate and fragile objects, while other robotic arms can have grippers that can grasp and lift loads weighing several tons.

Robotic arms can be equipped with any type of tool. These tools are used with precision, accuracy, speed, and repetitiveness that can not be matched by humans.

These robotic arms can have a multitude of sensors and vision systems capable of viewing images to aid with their computer-based control. That sensor and vision feedback can be used with artificial intelligence to make decisions about the behavior of the robotic arm.

Industrial robots and automation are an important part of the manufacturing of most products produced in today’s world.

Industrial Robots Main Components

The four main parts of an industrial robot are the manipulator, the controller, the human interface device, and the power supply.

The manipulator is the arm and can move in various different directions. On the V5 Workcell, the arm moves from a V5 Smart Motor acting as the actuator, which provides the force to move the arm. On an industrial robot, the force can come from electric motors, air pressure in pneumatic cylinders, or fluid pressure in hydraulic cylinders.

The arm has a controller which is the “brain” of the system. The controller holds the programming code and receives signals from the system (input), processes the signals, and then sends signals out to the system (output) to control the robot.

One type of input may come from the human interface device, such as a teach pendant. These devices can be used to program the arm and control its movement.

The last component is the power supply which is where an industrial robot gets its energy for its controller and actuators. This is typically in the form of electrical energy.