Understanding the Workcell Hardware

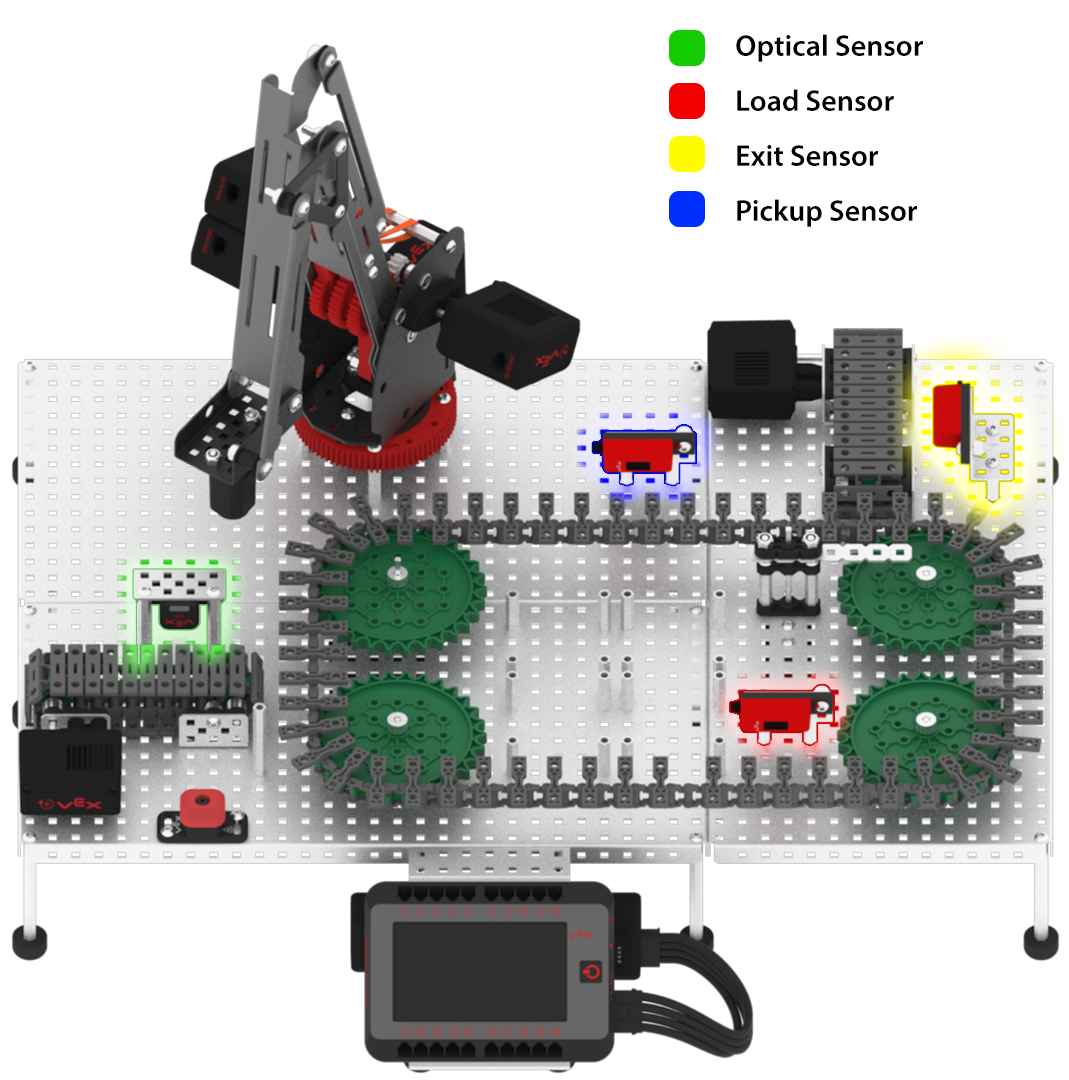

In this Lab, sensors were added to the Workcell in order to trigger the different movements of the conveyor belts. There are three different VEX Infrared Line Trackers as well as an Optical Sensor added to the Workcell. The names of these additions are the following:

- Optical Sensor: Optical Sensor to determine the presence and color of a disk.

- Load Sensor: Line Tracker to determine if a disk has been successfully loaded onto the Transport Conveyor.

- Pickup Sensor: Line Tracker to determine if a disk has passed the Diverter on the Transport Conveyor and is ready for pickup with the arm mounted on the VEX V5 Workcell.

- Exit Sensor: Line Tracker to determine if a disk has been discarded off of the Workcell via the Exit Conveyor.

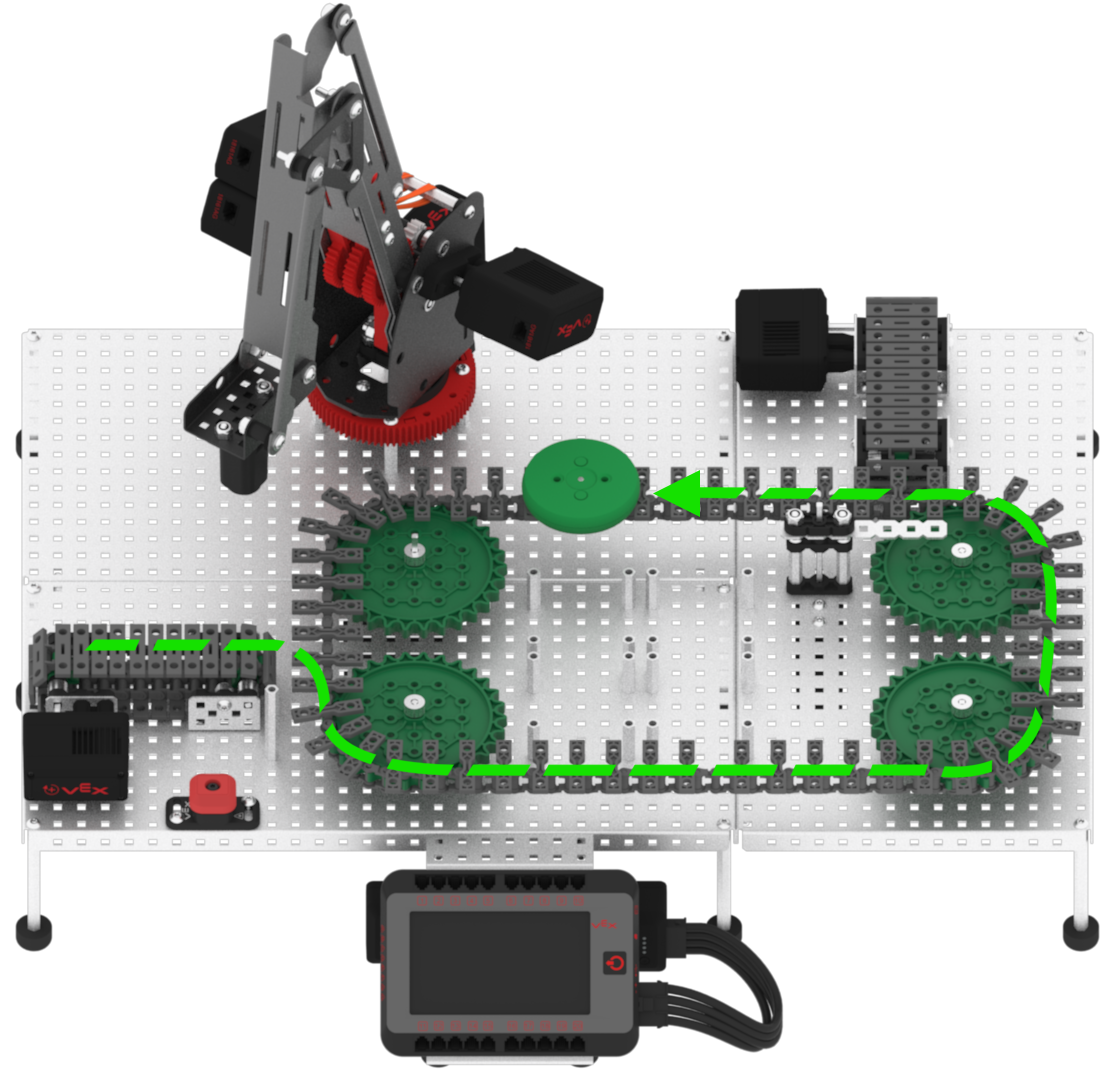

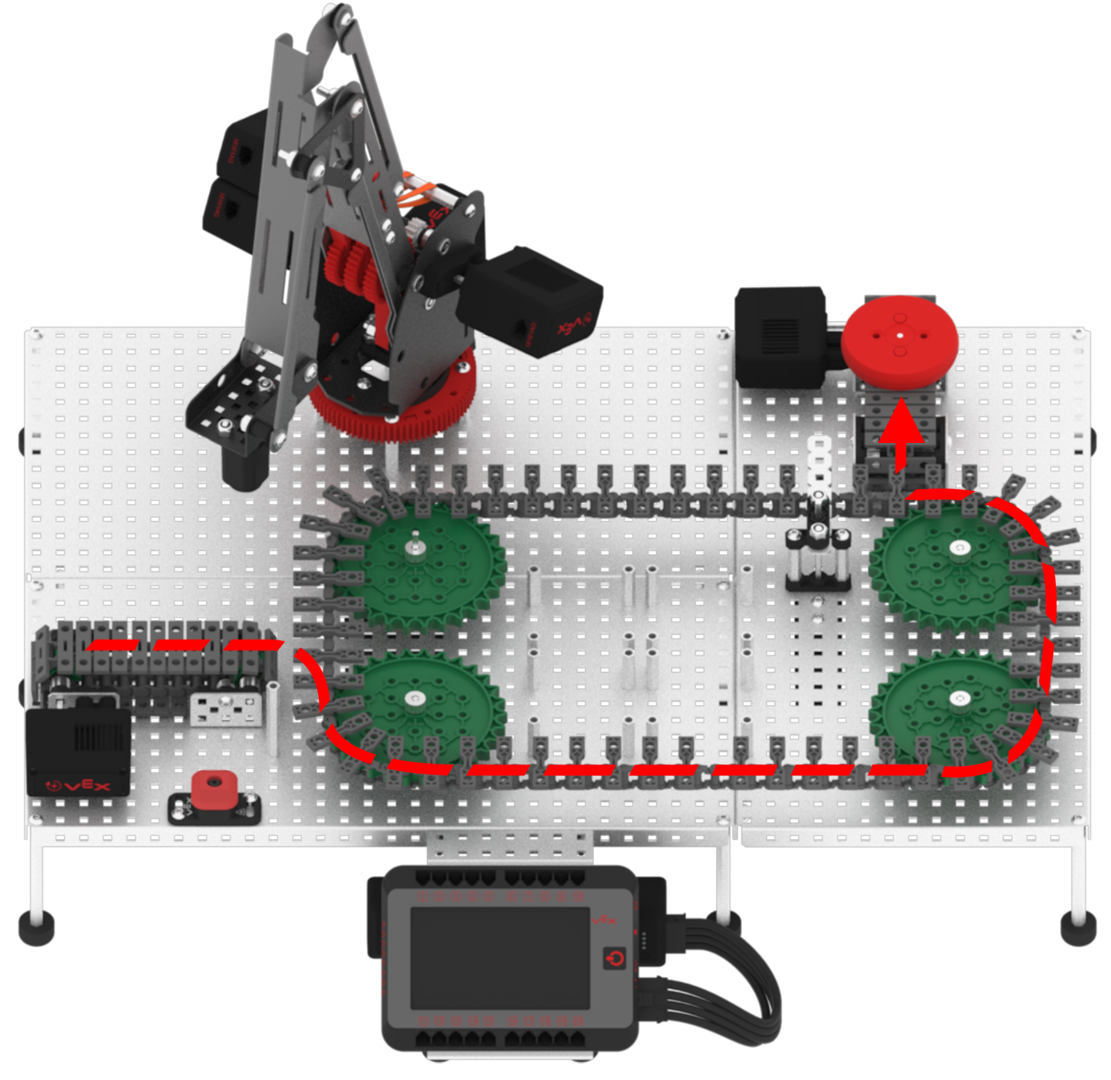

In this activity, you will program red disks to be diverted off the conveyor system, and program green disks to travel through the system and stop in front of the arm mounted on the V5 Workcell in any order.

The red disk, acting as a faulty package or product, will begin at the Entry Conveyor, travel through the Transport Conveyor, and be diverted off to the Exit Conveyor.

The green disk, acting as an acceptable package or product, will begin at the Entry Conveyor, travel through the Transport Conveyor, pass the Diverter to continue on the Transport Conveyor, and then stop at the Exit Sensor.