Disk Feeder Example

![]() Teacher Toolbox

-

Introduce the Play Section

Teacher Toolbox

-

Introduce the Play Section

In this Play section, groups will be introduced to the Disk Feeder on the Workcell's conveyor system. They will build a VEXcode V5 project to dispense and move three green disks through the conveyors using the Disk Feeder, sensor feedback from the Optical Sensor, and the Line Trackers.

What the Teacher Will Do:

- Bring students together for whole class instruction.

- Introduce the Lab to the students.

- In this Lab, students are introduced to the Disk Feeder on the Workcell's conveyor system. Explain to students that in previous Labs they explored how to sort disks using the Workcell's conveyor system. Now, they will further automate the disk sorting process by adding the Disk Feeder to the Workcell.

- Using the Disk Feeder allows multiple disks to be dispensed onto the Workcell in an autonomous fashion, so that a disk does not need to be manually placed onto the entry conveyor each time.

-

Explain to students that they will code the first green disk to be accepted and stop in front of the pickup sensor, and the second and third green disk will be rejected and diverted off of the exit conveyor.

-

Tell students they will be introduced to using Boolean variables in their VEXcode V5 project to track if a green disk has already been accepted. This allows any other green disks introduced via the Disk Feeder to be rejected.

- Show the video below to the class so they can see the end result of their project. Encourage students to come back and rewatch this video while they code if they need help remembering how the conveyors, diverter, or disks being dispensed from the Disk Feeder should move.

- Tell students that they will begin the activity by opening the ‘Arm Workcell - With Sensors’ example project.

![]() Teacher Toolbox

-

Facilitating the Disk Feeder Example page

Teacher Toolbox

-

Facilitating the Disk Feeder Example page

What the Teacher Will Do:

- Keep students together for a whole-class discussion about the activity.

- Instruct students that they will be working together in their groups to follow the steps on this page.

- Ensure each group of students has their devices to run VEXcode V5 and to view this page in the Lab.

- Tell students to check in with you once they have completed the steps on this page.

- Break students off to work within their groups. Walk around the room as students are working to answer any questions if they arise.

- As groups check in, ensure they have built their project correctly before moving on. Guidance for the check in is provided in a Teacher Toolbox at the bottom of this page.

For more information about how to facilitate this activity, go to the V5 Workcell Educator Certification.

In this section, you will be introduced to the Disk Feeder on the Workcell's conveyor system.

You will build a VEXcode V5 project to dispense and move three green disks through the conveyors using the Disk Feeder, sensor feedback from the Optical Sensor, and the Line Trackers.

You will code the first green disk to be accepted and stop in front of the pickup sensor, and the second and third green disk will be rejected and diverted off of the exit conveyor.

You will be introduced to using Boolean variables in your VEXcode V5 project to track if a green disk has already been accepted. This allows any other green disks introduced via the Disk Feeder to be rejected.

This video shows how the disks in the Disk Feeder, conveyors, and diverter will move when you complete the project.

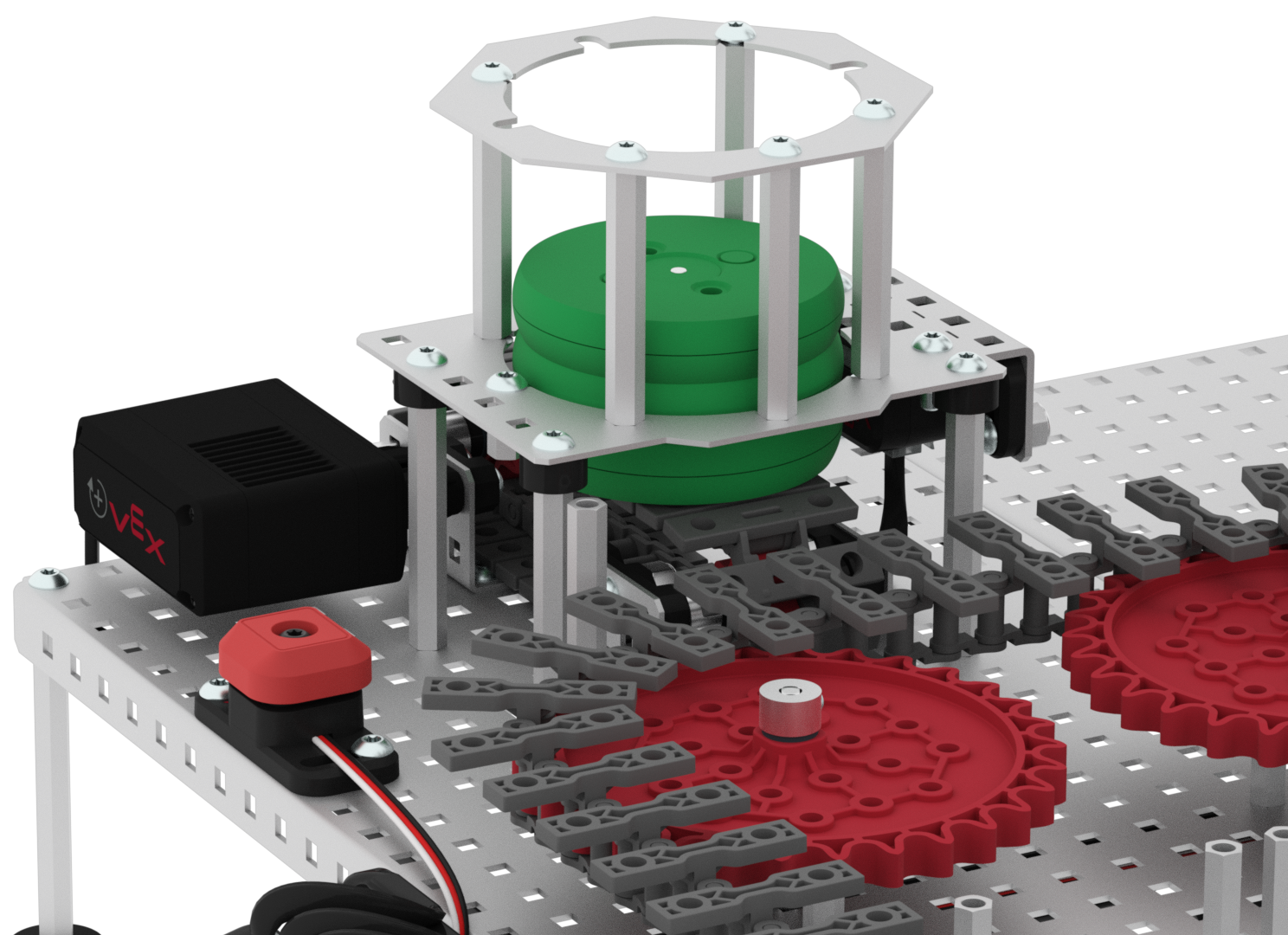

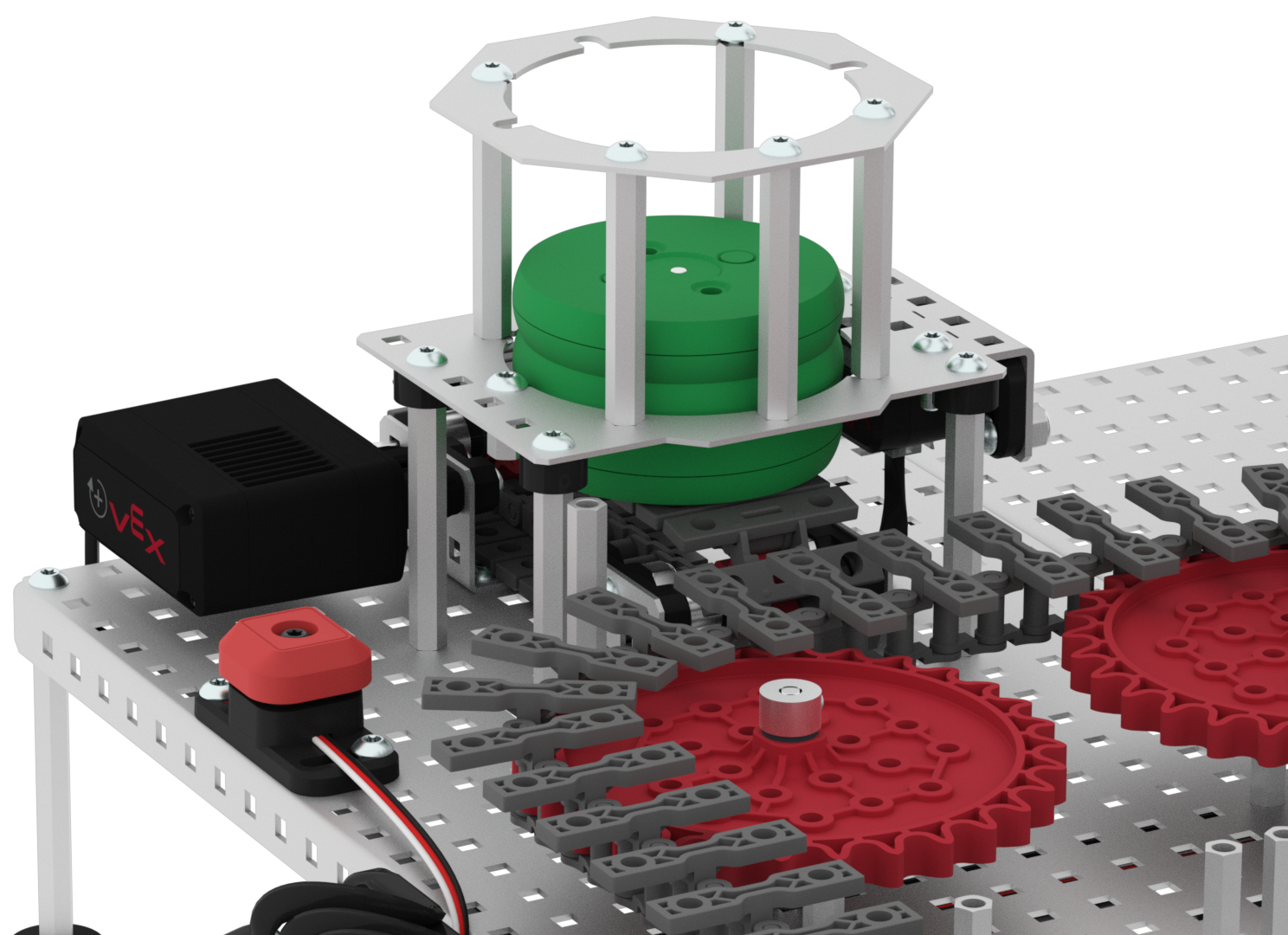

In the Seek section, the Disk Feeder was added to the Workcell. The Disk Feeder is used to dispense one disk at a time onto the entry conveyor in the Workcell.

Using the Disk Feeder allows multiple disks to be dispensed onto the Workcell in an autonomous fashion, so that a disk does not need to be manually placed onto the entry conveyor each time.

The Disk Feeder rests above the Optical Sensor. The Optical Sensor detects if an object is present, and if so, the color of that object. Used with the Disk Feeder, the Optical Sensor detects the color of the disk present on the entry conveyor, or the disk at the bottom of the Disk Feeder stack.

| Quantity | Materials Needed |

|---|---|

| 1 per group |

V5 Workcell |

| 1 per group | |

| 1 per group |

Engineering Notebook |

| 1 per group |

Device to run VEXcode V5 |

| 1 per group |

Micro-USB cable |

| 3 per group |

Colored Disks (3x green) |

In order to code the first green disk to be accepted, and any additional green disks to be rejected, you first need to build the 'Lab 11- Disk Feeder' project and test the functionality of the Disk Feeder.

This will give you experience adjusting the speed and duration of the entry conveyor for the Disk Feeder, as well as a visual example of how the disks are dispensed from the Disk Feeder onto the transport conveyor.

In VEXcode V5, follow the steps in this video to open the 'Arm Workcell - With Sensors' example project, input your mastering values, name, and then save the project as 'Lab 11- Disk Feeder'.

Ensure you are using your mastering values, and not the ones displayed in this video.

In the previous Lab, you have already coded a green disk to move from the entry conveyor to the transport conveyor.

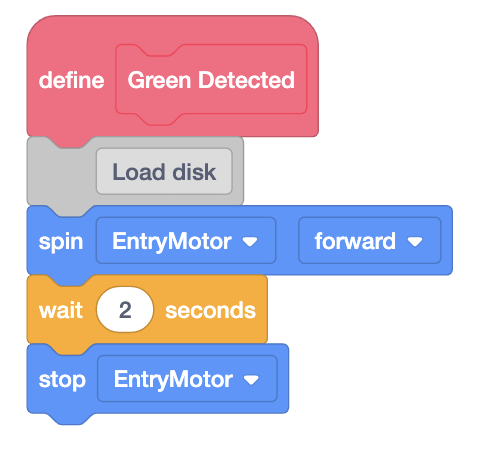

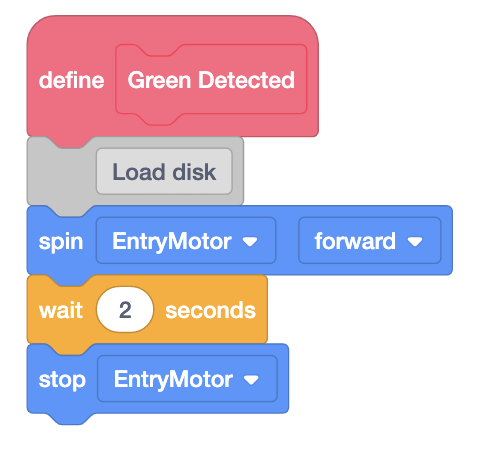

Add blocks to the {Define Green Detected} hat block to create the stack of blocks shown in this image.

These blocks will code a green disk to be dispensed from the Disk Feeder on the entry conveyor onto the transport conveyor.

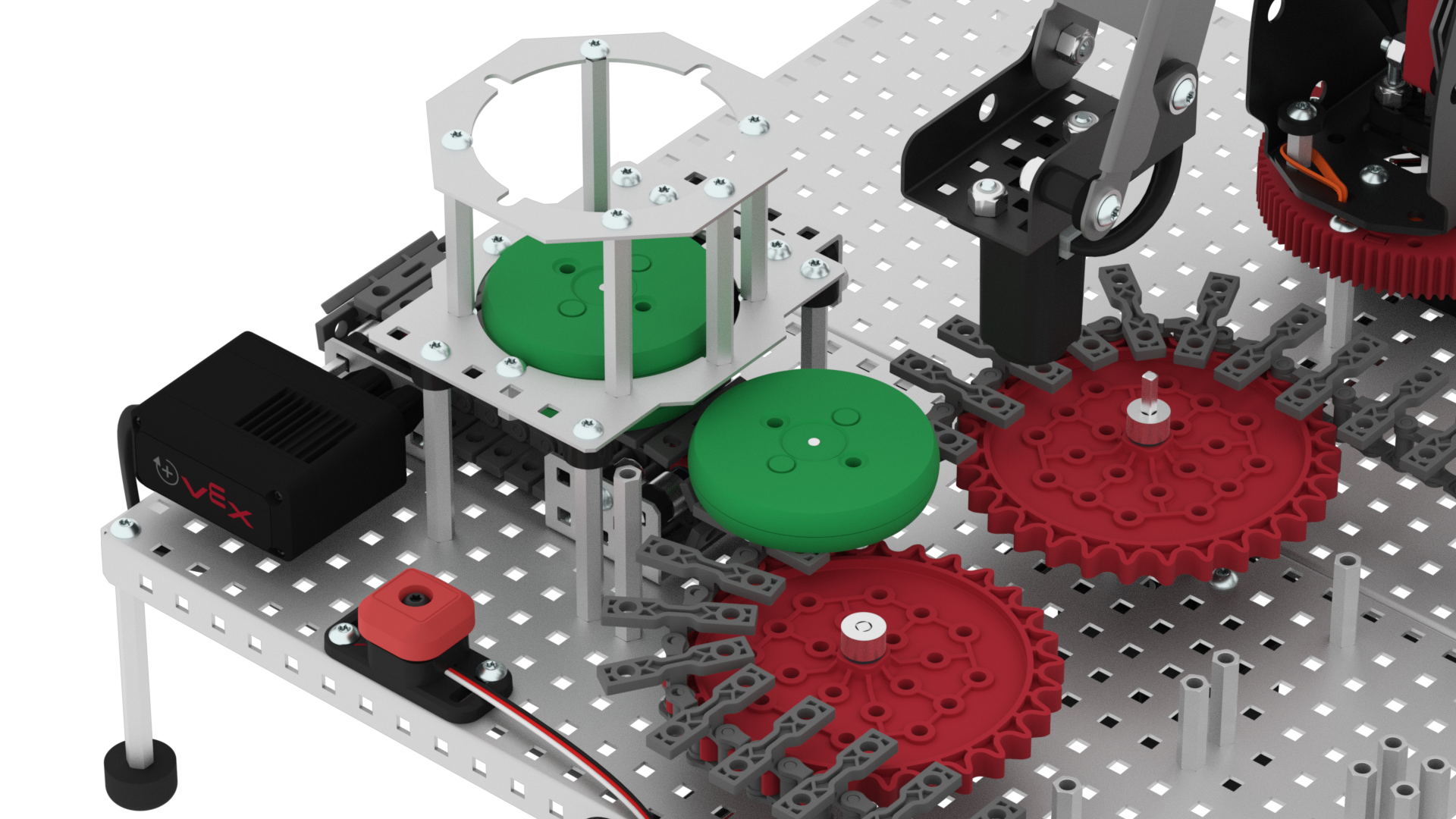

Load three green disks into the Disk Feeder and download and run the project.

Observe the Disk Feeder in action.

The speed and duration that the entry conveyor spins will need adjusted to dispense one disk correctly.

Once you have observed the Disk Feeder in action, stop the project.

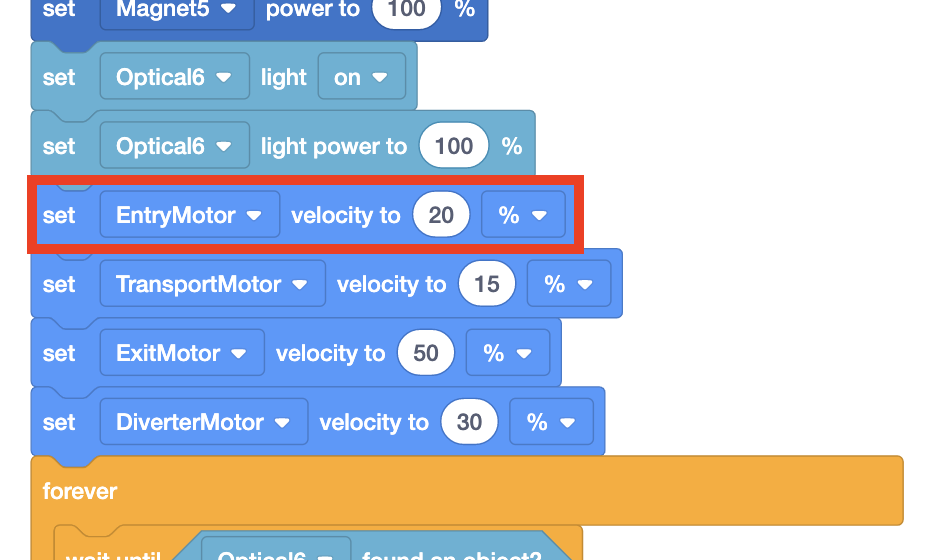

Adjust the parameters of the [Set motor velocity] block and the [Wait] block that control the entry conveyor.

The velocity and duration that the entry conveyor spins may currently be too fast and need to be lowered.

Once the parameters have been adjusted, download and run the project again to test how well the Disk Feeder dispenses one disk using the new parameters.

Once you have observed the Disk Feeder in action, stop the project.

Continue to adjust the parameters of the entry conveyor as needed until the Disk Feeder dispenses one disk properly from the entry conveyor to the transport conveyor.

Once you have dispensed one disk properly from the Disk Feeder, stop the project and check in with your teacher.

![]() Teacher Tips

Teacher Tips

- Saving a VEXcode V5 project may look different depending on the device that your students are using. For more information on how to save on a specific devices, view the Save a Blocks Project (iPad, Chromebook, Windows, macOS) articles from the Knowledge Base.

- For more information on opening example projects, view this article from the Knowledge Base.

- For more information on any of the blocks in VEXcode V5, view this article from the Knowledge Base on the Help feature.

- Remind students that their mastering values will be different than the one shown in the video. Students should be using their values, and not the values from the video.

- For additional tips, go to the V5 Workcell Educator Certification.

![]() Teacher Toolbox

-

Troubleshooting

Teacher Toolbox

-

Troubleshooting

If groups are finding issues with dispensing one disk correctly from the Disk Feeder, try the following troubleshooting techniques.

- Check the VEXcode V5 project.

- Check that students have added these blocks to the {Define Green Detected} hat block, and that the parameters of the [Spin] and [Stop motor] blocks are set to EntryMotor as opposed to any of the other motors on the Workcell.

- Ensure students are re-downloading their project each time they make a change and before they run the project.

- Ensure students are adjusting the velocity for the entry conveyor and not the transport conveyor, exit conveyor, or diverter.

- Check that students have added these blocks to the {Define Green Detected} hat block, and that the parameters of the [Spin] and [Stop motor] blocks are set to EntryMotor as opposed to any of the other motors on the Workcell.

- Check the build.

- There may be a mechanical issue with your Workcell. Instruct students to look at the Lab 11 build instructions first and verify that they attached the Disk Feeder correctly to their Workcell.

![]() Teacher Toolbox

-

Check in

Teacher Toolbox

-

Check in

Review the following with the group during their check in:

- Ask groups to run their project for you to demonstrate that they have have dispensed one disk properly from the Disk Feeder.

- If groups did not dispense one disk properly from the Disk Feeder, follow the steps in the Troubleshooting Teacher Toolbox above.

- Ask students the following questions as they are demonstrating their project.

- How did the Disk Feeder dispense disks the first time you observed it in action? Did it dispense disks too fast, too slow, or not at all?

- Based on your initial observations, how did you edit your project to dispense one disk correctly?

- Did the Disk Feeder dispense one disk properly after you adjusted the parameters the first time? If not, what parameter(s) did you adjust more than once in order to get it to dispense properly?