Industrial automation is something we interact with every day, from receiving a delivery to shopping at the grocery store.

In this Lesson, you will learn:

- What industrial automation is.

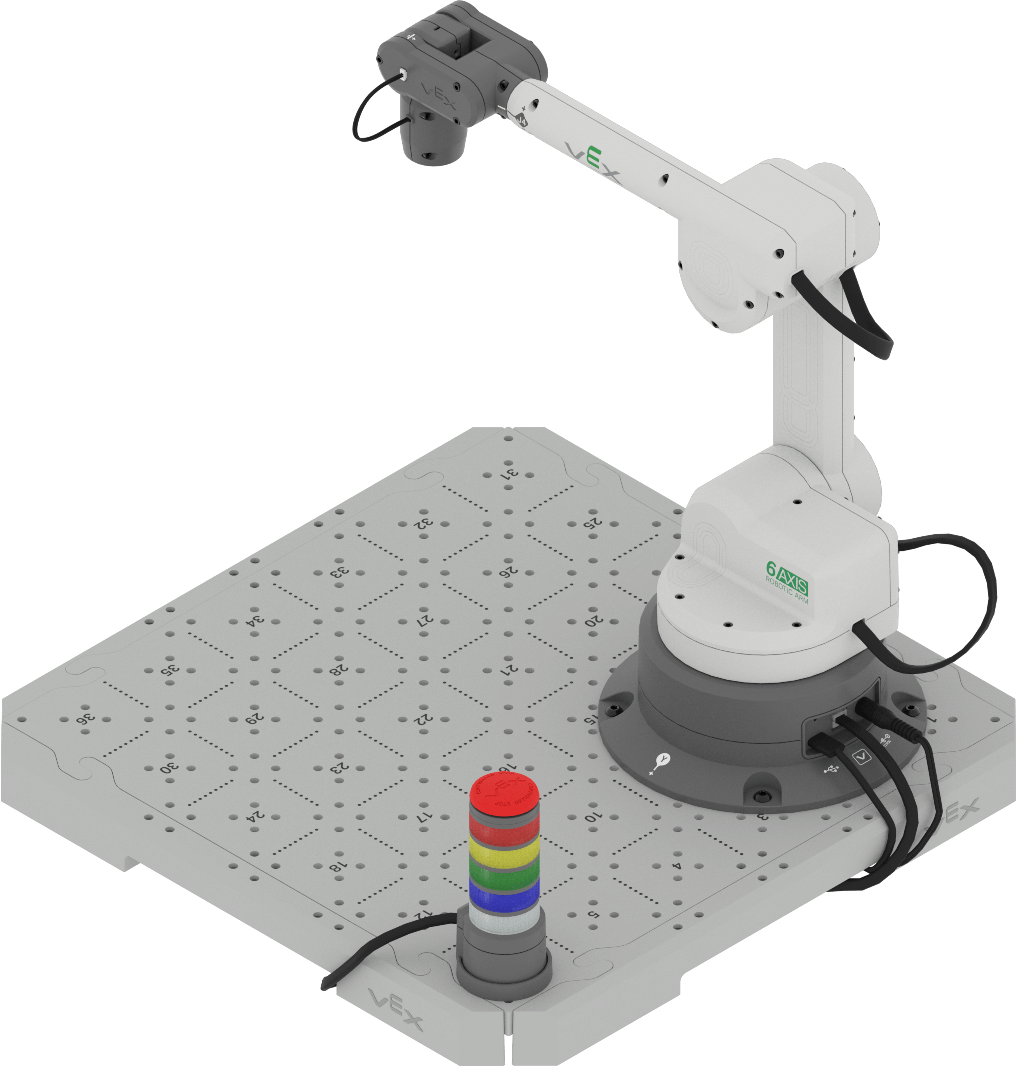

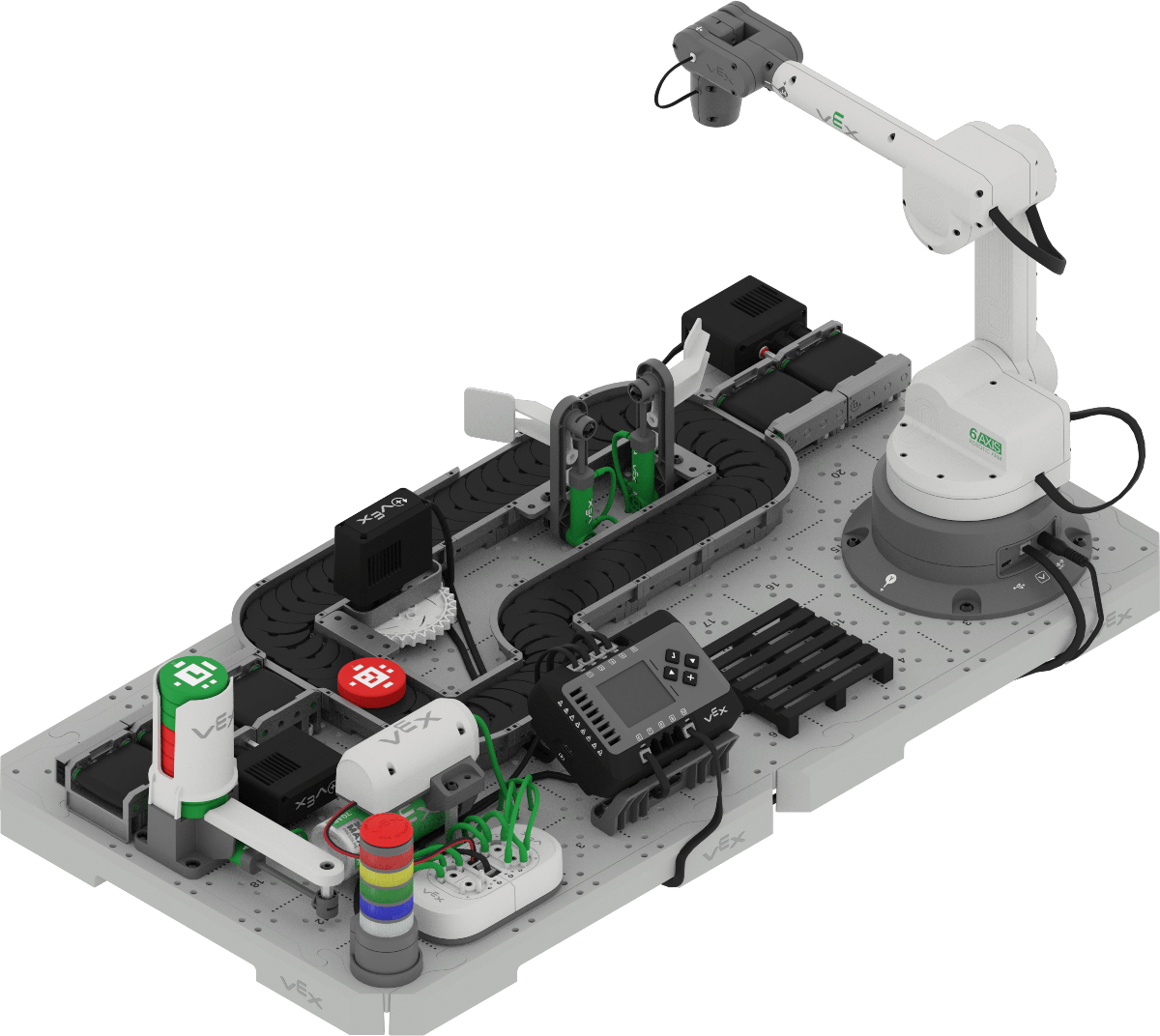

- What a workcell is and how it is used in manufacturing.

- What a robotic arm is and how it moves.

- How the CTE 6-Axis Robotic Arm relates to these concepts.

At the end of this Lesson, you will discuss what you learned as you answer questions about the 6-Axis Arm in your engineering notebook.

Introduction to Automation

What is industrial automation?

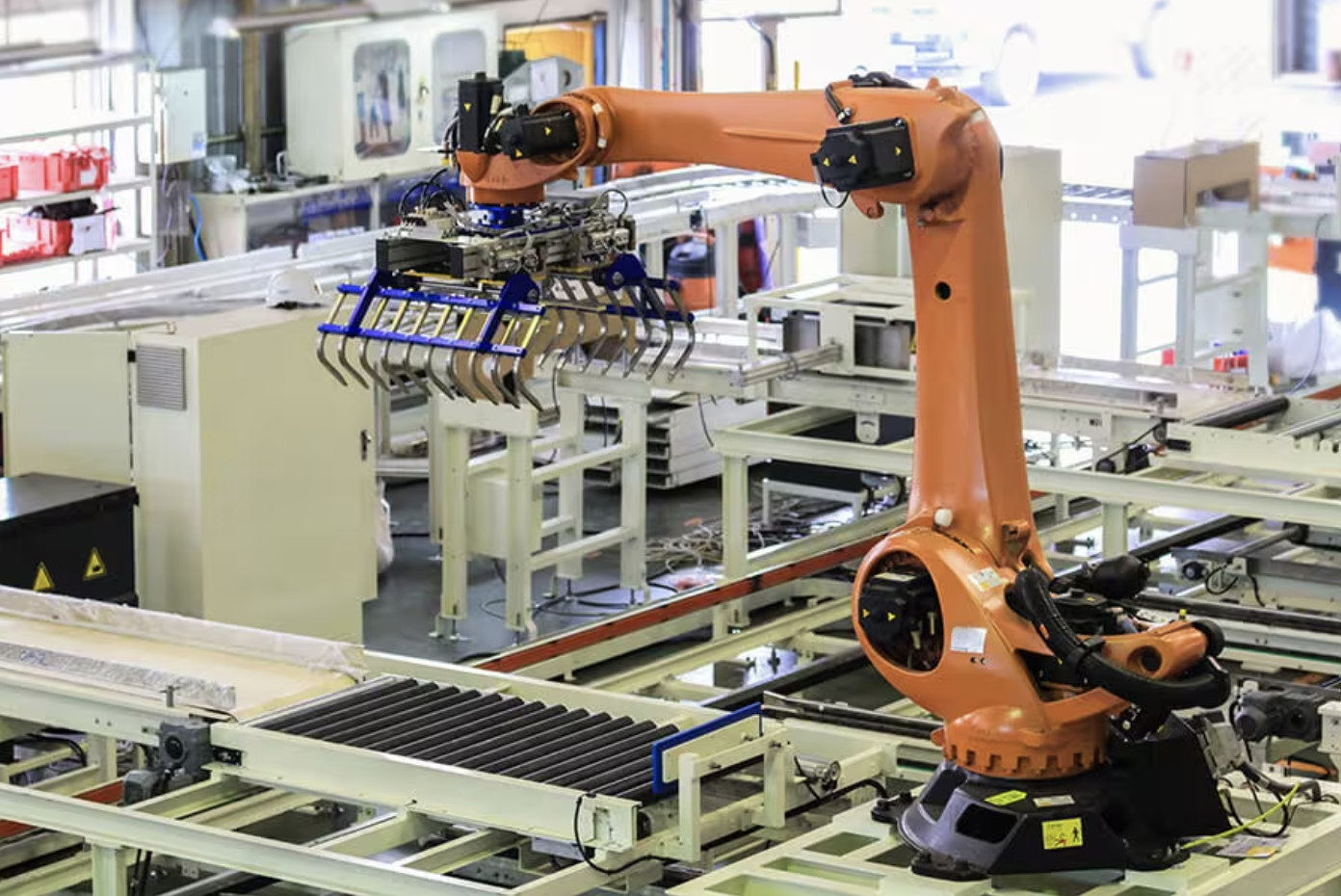

Industrial automation is the use of technology and machines to streamline and improve manufacturing and production processes in factories. In modern industrial factories, automation is central to a variety of tasks aimed at boosting efficiency, ensuring safety, and enhancing precision. These include manufacturing operations where robots complete various tasks, like:

- welding and soldering for metal fabrication.

- painting and coating.

- material handling, like moving, sorting, and packaging products.

What is a workcell?

A workcell is the grouping of machines, people, and other equipment companies use in their manufacturing production process. These cells are often implemented to reduce the costs associated with production and ramp up productivity. Many companies also significantly reduce the rate of error by putting workcells into place.

For example, in a manufacturing facility, the machines involved in the process (like robotic arms and conveyors) would be arranged so the goods being produced move smoothly and seamlessly from one stage to the next. This would only be possible if the machines are grouped in workcells that facilitate the logical progression of the goods being produced — from raw materials at one end to the finished product at the other.

What is a robotic arm?

A robotic arm is a programmable machine with joints and segments that replicate the motion of a human arm. Robotic arms can be equipped with many types of tools so they can complete a variety of tasks, like welding, painting, cutting, and grasping objects. These tools are used with precision, accuracy, speed, and repetitiveness that can not be matched by humans.

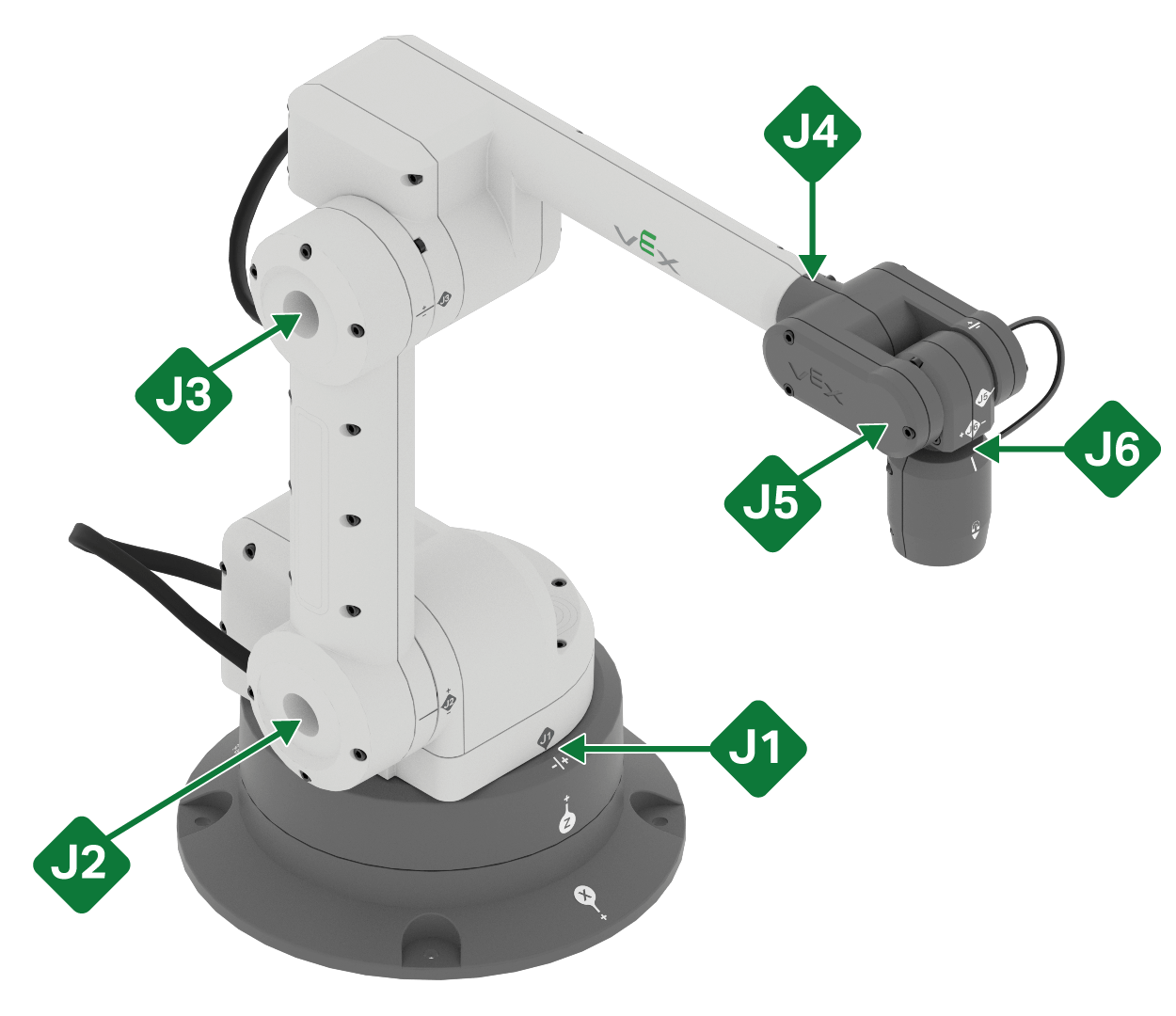

What does the '6-Axis' part of '6-Axis Robotic Arm' mean?

Robotic arms move in multiple axes. Axes in the context of a robotic arm refer to the number of degrees of freedom, or the number of independent movements the robot can make. Each axis represents a potential range of motion. In the case of the 6-Axis Robotic Arm you will use in this course, there are six degrees of freedom. These axes allow the 6-Axis Arm to pivot side to side, move up and down, and rotate. These movements, when used together, enable the robotic arm to position a tool in any orientation within its reach, allowing for complex maneuvers to complete automated tasks in an industrial setting.

Each axis of the CTE 6-Axis Robotic Arm corresponds to a joint. The joints are labeled J1 - J6 on the 6-Axis Arm, as shown in this image.

Industrial Automation in Our Everyday Lives

Factory automation and industrial robots are woven into our everyday lives, often without us realizing their impact. Consider the overnight delivery of a package or the consistently stocked shelves at a grocery store. These everyday conveniences are made possible by advanced manufacturing processes, where automation and robotics play an important role.

When an online order is placed, it is processed by an automated system, and assigned to a warehouse. In these warehouses, industrial robots play a crucial role, navigating the aisles and retrieving items with precision and speed. These robots are capable of moving in multiple directions and handling products with care. They work alongside humans to sort, package, and prepare your order for shipment, all within hours.

Activity

Now that you have learned a bit about industrial automation, workcells, and robotic arms, it is time to discuss and document your ideas about how the 6-Axis Arm fits into that context. Discuss each of these prompts with your group and record your answers in your engineering notebook.

- What are some tasks you think a 6-Axis Arm could perform within a Workcell system, such as the VEX CTE Workcell?

- What are some advantages of using a robotic arm instead of manual labor for tasks?

- Choose one item in your classroom. Describe how a robotic arm could be used in each step of the production process to get that item from the factory to your classroom.

Check Your Understanding

Before beginning the next Lesson, ensure that you understand the concepts in this Lesson by answering the questions in the document below in your engineering notebook.

Check Your Understanding questions > (Google Doc / .docx / .pdf)

Select Next > to get started with your 6-Axis Arm.