Lesson 1: Pallets

In the previous Unit you moved the 6-Axis Robotic Arm using a combination of absolute and relative movement to draw shapes and patterns. You will build on this as you use this movement to enable the 6-Axis Arm to move objects onto pallets. First, you will be introduced to what pallets are and the important role they play in transportation and supply chain logistics.

In this Lesson you will learn:

- What a pallet is.

- Why pallets are important in an industrial and manufacturing setting.

- How robotic arms interact with pallets to move objects in an organized and efficient way.

By the end of this Lesson you will have foundational knowledge about pallets, and add pallets to the CTE Workcell Tile.

Why Use a Pallet?

The challenge of moving products effectively and efficiently from a factory setting to their final destination can involve complex transportation and logistics. Think about the way you move your own items each day. You likely use a backpack to transport books, papers, a water bottle, and other items between home and school. You may have a backpack with one large pocket where books, papers, pens, and other items are all mixed together and piled up, or a highly organized backpack with pockets for books and pens and folders for loose paper. In either case, the amount of things you can pack is roughly the same and the items aren't highly affected by being disorganized.

Now let's think about a lunch tray in the cafeteria. How you organize your tray can affect the items you carry. You want to make sure your drink does not spill on your sandwich, or that an apple does not roll into other foods. You can carry many items on the tray, but this is only an efficient choice if the items are still edible once you reach your table. Here, the way that items are organized matters – this is the same with a pallet.

Shipping large quantities of products is similar – you want to be able to move objects safely, without things getting crushed or damaged, and be able to find items in a fast and efficient way on the other end. You would much rather have an organized tray, rather than a haphazard one. This is why pallets are used. Companies like Amazon or UPS have billions of packages to keep track of – those packages need to be well organized to keep shipping schedules running smoothly.

Pallets are used to move large quantities of items in an organized and efficient manner. Just like the organized backpack, pallets allow for a precise and effective means of shipping products.

What is a Pallet?

A pallet is a flat transport structure, typically made of wood, plastic, or metal. It serves as a stable base for assembling, storing, handling, and transporting goods as a unit load. You may have seen pallets in warehouses or big box stores. Pallets are designed to be easily moved using forklifts, pallet jacks, or conveyors.

Part of what makes pallets so universal in shipping around the world is that they are standardized. Standard pallets come in set sizes. This uniformity is crucial for optimizing the loading and unloading processes in warehouses, trucks, and shipping containers. Pallets allow for efficient storage and can be stacked to maximize vertical space in warehouses.

Benefits of Using Pallets in Industry

In addition to their standard sizes, pallets offer other benefits as well. Using pallets reduces the risk of injury as workers are not required to lift and carry individual items. Pallets elevate the goods off the floor, protecting them from dirt, debris, and water damage.

Pallets also allow for quick movement of a large quantity of goods at once. This is further optimized when pallets are stacked efficiently. All of this leads to cost savings, as companies look to ship more products more quickly.

There are also benefits in terms of sustainability. Wooden pallets are able to be fixed, and are reusable. This extends their life cycle and helps reduce waste.

Connection to Robotic Arms

Robotic arms, when used in conjunction with pallets, enable large quantities of goods to be organized, packed, and shipped efficiently and safely every day around the world. By automating repetitive and potentially hazardous tasks, robotic arms improve workplace safety. Human labor, while essential in many areas, has limitations. Especially for repetitive tasks, like stacking packages on pallets, humans are limited in their strength, speed, endurance, and precision in ways that robots are not. Robotic arms can move faster and more consistently than humans, especially over long periods. They are capable of working 24 hours a day, seven days a week, moving large and heavy objects without fatigue. Rather than risking the physical strain and injury for human workers, using a robotic arm can maintain a constant pace and operational efficiency.

There are other advantages of robotic arms, like accuracy, cost-effectiveness, and integration with other technologies. Robotic arms can be programmed for precise movements, ensuring that packages are securely packed, and optimally organized, reducing the risk of damage. While the initial investment in robotics can be significant, over time, they are cost-effective due to reduced labor costs and increased productivity. Robots also offer scalability, allowing companies to easily ramp up operations to meet increased demand.

Robotic arms can also be integrated with advanced technologies like sensors, machine vision, and AI. This integration allows for smart decision-making, such as identifying and sorting different types of packages and optimizing pallet loading patterns. In large corporation warehouses, this technology integration enhances the overall efficiency of the supply chain, from inventory management to shipping and delivery.

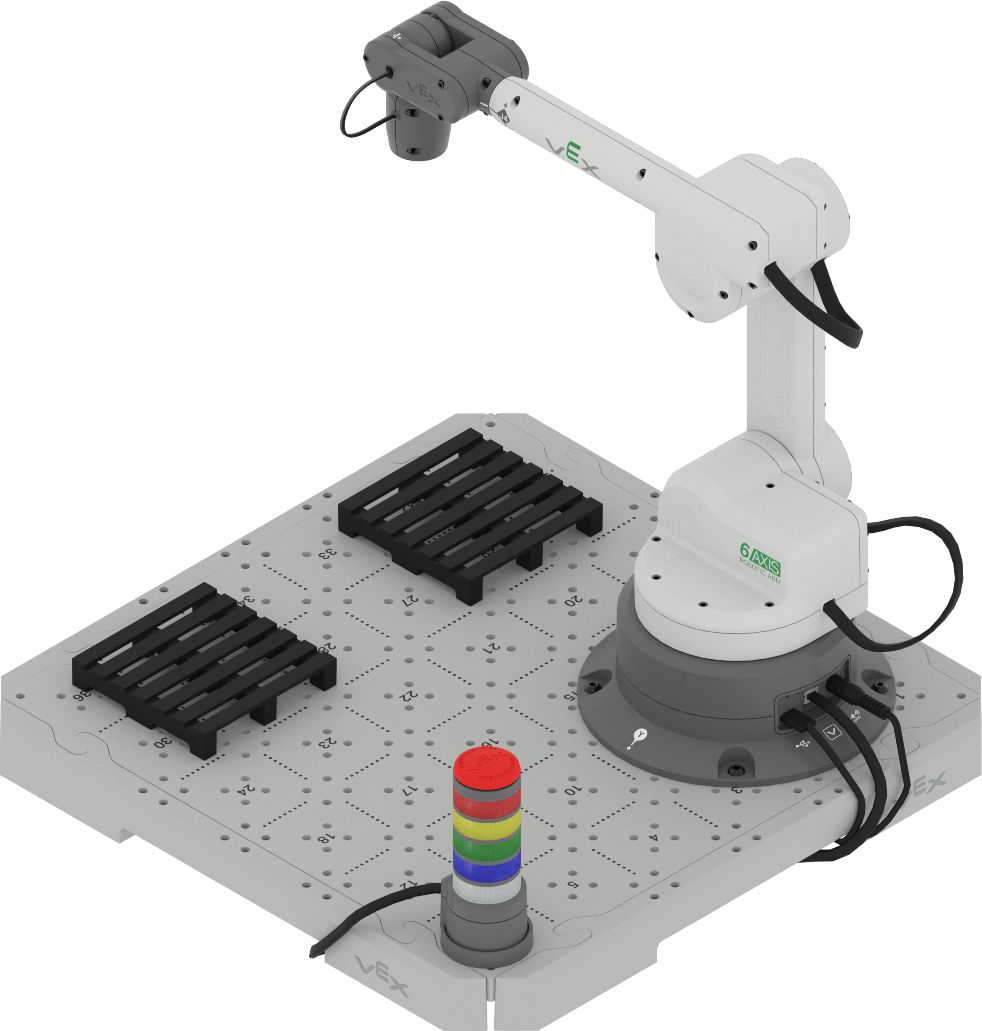

Adding Pallets to the CTE Workcell Tile

The 6-Axis Robotic Arm Kit includes pallets that can be attached to the CTE Tile, to mimic the way pallets are used in real world scenarios.

Check Your Understanding

Before beginning the next Lesson, ensure that you understand the concepts in this Lesson by answering the questions in the document below in your engineering notebook.

Check Your Understanding questions > (Google Doc / .docx / .pdf)

Select Next > to move on to Lesson 2.