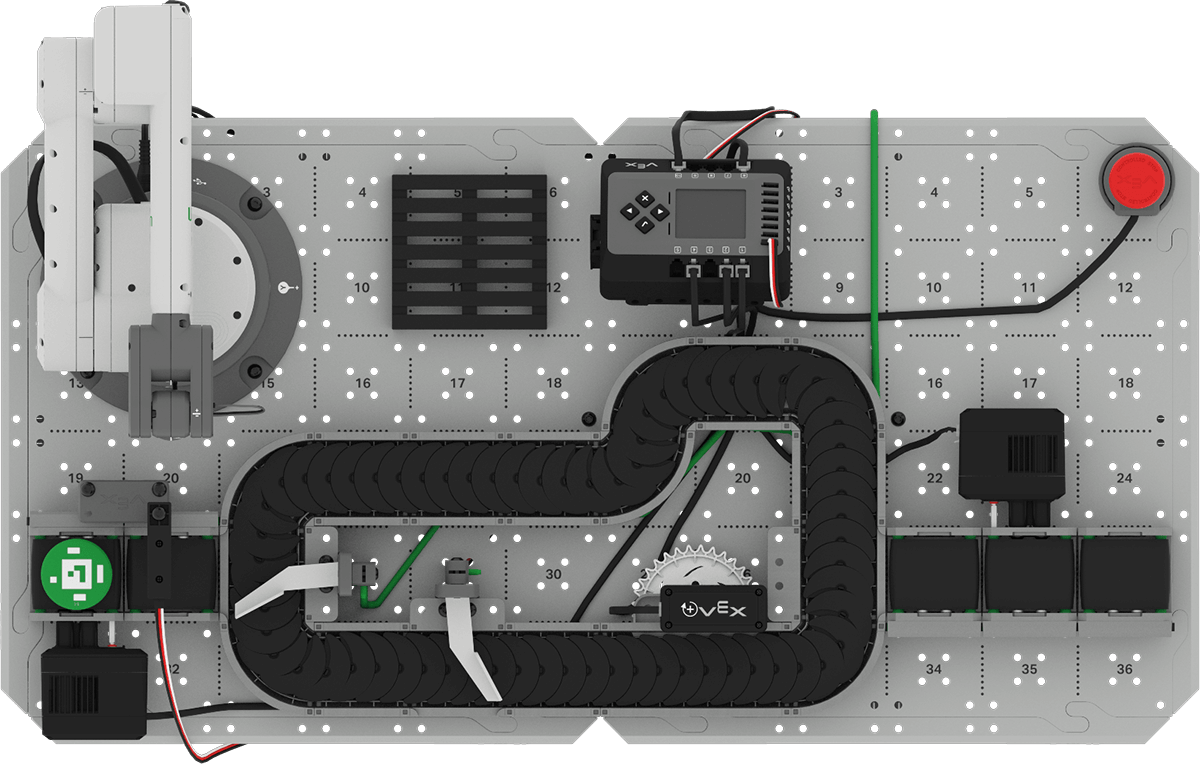

In the previous Unit, you learned about how the Optical Sensor reports the hue value and proximity of detected objects, and you coded nested conditional statements to sort Disks by color using the Optical Sensor. In this Unit, you will build on that knowledge by learning about how conveyors are used within the industrial automation industry, the importance of time-based movements, and how the Object Sensor is used to detect the presence of an object.

By the end of the Unit, you will successfully transport a Disk along the conveyors using time-based movements and you will code the Object Sensor to stop the Exit Conveyor when a Disk is detected.

Co-Create Learning Targets

Now that you have watched the video, you know that you will code the conveyors to transport a Disk along the conveyor and code the Object Sensor to stop the Exit Conveyor when a Disk is detected. You will first learn about how linear and serpentine conveyors are used in industrial automation. Then, you will learn what time-based movements are, and their importance in conveyor operations. Additionally, you will learn how the Object Sensor functions and how to interpret the data it produces. Finally, you will apply all these skills to create a project that quickly transports a Disk from the Entry Conveyor to the Exit Conveyor, halting the Exit Conveyor when a Disk is detected by the Object Sensor.

You will co-create learning targets with your group and your teacher to capture these goals so that you have a shared understanding of your learning goals for the Unit. You will write your learning targets in your engineering notebook so you can refer to them throughout the Unit.

It is helpful to phrase learning targets in the form of "I can" statements. Example learning targets for this Unit could include:

- I can explain the purpose of conveyors in industrial manufacturing.

- I can configure a motor in VEXcode EXP.

- I can explain the difference between an analog sensor and a digital sensor.

- I can create a project that moves a Disk from the Entry Conveyor to the Exit Conveyor as quickly as possible and uses the Object Sensor to stop the Exit Conveyor when a Disk is detected.

To create your learning targets, first brainstorm what you will need to know to complete the activities shown in the video above. Make a list in your engineering notebook of what you will need to know, learn, and do, like this:

- Identify what a conveyor is.

- List the steps to configure a motor in VEXcode EXP.

- Identify the characteristics of an analog sensor and a digital sensor.

- Collaborate with my group to complete the Putting It All Together Activity.

Next, co-create learning targets based on your list. Think about how each of the things you listed can be framed into a learning target, using "I can" statements. You can use this template to help you write your learning targets in your engineering notebook. (Google Doc / .docx / .pdf)

For example, the list item, "List the steps to configure a motor in VEXcode EXP" can be shifted to a learning target of, I can configure a motor in VEXcode EXP.

The following table shows an example of how the Learning Target Organizer in your engineering notebook could be filled out.

| Learning Target Category | Learning Targets |

|---|---|

|

Knowledge Targets What do I need to know and understand in order to be successful in the Unit? |

|

|

Skill Targets What can I demonstrate to show I understand the concepts and skills needed to be successful in the Unit? |

|

|

Product Targets What can I record in my engineering notebook to demonstrate and expand my knowledge about the concepts and skills needed to be successful in the Unit? |

|

Share your learning targets with your teacher. Adjust them as needed so that you, your group, and your teacher are all in agreement.

Vocabulary

In this Unit, you will learn how to use time-based movements to code the conveyor system to transport a Disk, as well as how to code the Object Sensor to detect when a Disk enters the Exit Conveyor. This vocabulary list is here to provide reference for any new terms you may come across. Record this vocabulary in your engineering notebook. Use this list as reference as you work through the Unit and encounter words you may not be familiar with.

- Linear Conveyor

- A conveyor that transports materials along a straight path, or linearly, and serves as the entry and exit points for passing objects onto and off of the larger serpentine conveyor.

- Serpentine Conveyor

- A conveyor that consists of interconnected belts and platforms arranged in a series of twists and turns, resembling a snake-like shape.

- Analog Sensor

-

A type of sensor that continuously reports values within a given range without any digital conversions.

- Digital Sensor

- A type of sensor that takes readings and converts those readings into specific numerical values.

- Reflectivity

- A measurement of the amount of light that bounces off the surface of an object.

- Threshold

- Used to determine if a value is above, below, or within an acceptable range.

- Object Sensor

- A 3-wire analog sensor that consists of an infrared LED and an infrared light sensor to detect the presence of an object; the sensor returns any value between 0% and 100% light reflectivity.

- Diverter

- A conveyor component that redirects or sorts items onto different paths or destinations within the conveyor.

| Quantity | Materials Needed |

|---|---|

| 1 per group | |

| 1 per group |

Computer |

| 1 per group |

VEXcode EXP |

| 1 per group |

Disks |

| 1 per student |

Engineering Notebook |

Select Next > to move to Lesson 1.